What Is Enterprise Asset Management Explained

Enterprise Asset Management, or EAM, is the strategic game plan for getting the most value out of every physical thing an organization owns—from the moment you buy it to the day you retire it. This is way more than just fixing stuff when it breaks. It's a complete approach to tracking, maintaining, and optimizing how your assets perform to cut costs and boost safety.

What Is Enterprise Asset Management At Its Core?

Think of EAM as the command center for a Formula 1 team. Every single part of that race car—the engine, the tires, even the tiniest sensor—is tracked, analyzed, and fine-tuned for peak performance. The goal isn't just to win one race. It's to manage the entire fleet of cars cost-effectively through the whole season.

That big-picture view is what really sets EAM apart from basic maintenance. It’s a business strategy that covers the entire journey of an asset, from the initial purchasing decision, through its operational life of scheduled upkeep and upgrades, all the way to its eventual decommissioning.

The Lifecycle View Of Assets

A core idea in EAM is managing an asset through its entire lifecycle. This proactive stance helps you squeeze every bit of value out of it at every stage.

For instance, a delivery company using EAM doesn’t just track fuel and repairs. It analyzes data to figure out the perfect, most cost-effective time to replace a vehicle. It’s a constant balancing act between rising maintenance costs and the big expense of buying a new truck.

This lifecycle approach leads to real, tangible savings. Instead of driving a vehicle until a catastrophic engine failure costs $15,000, the EAM system flags it for replacement when repair costs start creeping past a set limit. That move alone can save the company thousands in surprise expenses and crippling downtime.

"EAM provides a single source of truth for all physical assets, enabling organizations to shift from a reactive 'fix-it-when-it-breaks' model to a proactive, data-driven strategy that optimizes performance and minimizes total cost of ownership."

Beyond Maintenance To Strategic Decisions

Ultimately, EAM helps you make smarter financial and operational calls. A huge first step in that process is knowing exactly what you have, which is why it's so important to perform a comprehensive asset audit to get the baseline data you need.

This kind of strategic oversight is becoming more critical by the day. The global EAM market, valued at around USD 5.87 billion in 2025, is expected to hit USD 9.02 billion by 2030. That growth shows a massive shift toward optimizing physical infrastructure.

To give you a clearer picture, here’s a quick breakdown of what EAM focuses on.

Key Aspects Of Enterprise Asset Management At A Glance

| Core Function | Description | Practical Money-Saving Example |

|---|---|---|

| Asset Lifecycle Management | Tracking an asset from procurement to disposal, making strategic decisions at each stage. | Instead of running a pump until it fails, EAM data suggests replacement when repair costs exceed 60% of a new one's price, saving on a more expensive catastrophic failure. |

| Work Order Management | Creating, assigning, and tracking all maintenance tasks, both planned and unplanned. | A technician receives an automated work order on their tablet with the asset's full history, parts needed, and manuals, completing the job in one visit instead of two. |

| Preventive & Predictive Maintenance | Scheduling routine maintenance and using data (like sensor readings) to predict failures before they happen. | An HVAC system sensor flags unusual vibrations, triggering a preemptive repair that costs $200 instead of a $5,000 emergency replacement on a hot day. |

| MRO Inventory Management | Managing the spare parts and supplies needed for maintenance, repair, and operations (MRO). | The system automatically reorders filters when stock is low, preventing delays and avoiding expensive rush shipping fees to get a line running again. |

| Analytics and Reporting | Generating insights from asset data to identify trends, measure performance, and inform business decisions. | Reports show one model of vehicle costs 30% more in maintenance, guiding future purchasing decisions to save millions over the fleet's lifetime. |

As the table shows, it all boils down to using data to make smarter, more proactive decisions that save money and keep things running.

The main goals are pretty straightforward:

- Maximize Asset Uptime: Use predictive maintenance to schedule repairs before something breaks, keeping your operations smooth.

- Reduce Maintenance Costs: Move away from pricey emergency repairs and toward planned, more affordable preventive work.

- Improve Safety and Compliance: Make sure all equipment meets regulatory standards and is safe for your team to use.

- Extend Asset Lifespan: Get more productive years out of high-value equipment, which means a much better return on your investment.

Exploring the Core Components of a Modern EAM System

This image gets right to the heart of what a modern EAM can do. That sensor is feeding real-time data back to the system, which is the secret sauce for predictive maintenance. It’s all about spotting the small tremors before they become earthquakes that bring your operations to a halt.

To really get what enterprise asset management is all about, you have to look under the hood. A good EAM system isn't just a fancy spreadsheet; it's a collection of powerful, interconnected modules all working together to keep your assets running smoothly and save you serious money.

Let’s pull back the curtain on these core parts.

Asset Lifecycle Management

This is the big-picture view. It tracks an asset's entire story, from the day you decide you need it, through its purchase and daily use, all the way to its final retirement and disposal. This isn't just record-keeping; it's strategic oversight that makes sure you squeeze every ounce of value out of your investments.

Think of it like managing a fleet of ambulances. You don't just fix them when they break. You're tracking everything—initial cost, depreciation, fuel consumption, and the rising cost of repairs as they age.

Practical Money-Saving Example:

Your EAM system flags that Ambulance #7's repair costs over the past year have hit 65% of its current resale value. Instead of pouring more cash into a vehicle that's becoming a money pit, you make a data-driven call to sell it and invest in a new, more reliable model. That single decision can save you thousands in future repairs and fuel.

Work Order Automation and Management

At its core, EAM is about doing the right work, at the right time, on the right asset. This component is the engine that drives that process. It automates how work orders are created, assigned, and tracked from start to finish. Say goodbye to paper trails, missed calls, and confusion about who's doing what.

When a scheduled service is due or a repair request comes in, the system instantly generates a work order. It can automatically assign it to the right technician based on their skills and availability, attaching all the critical info they need—asset history, manuals, and necessary parts—right to their mobile device. To see how these workflows can be improved with smart dispatching tools, you can explore the full range of features available in systems like Resgrid.

Practical Money-Saving Example:

A fire station's bay door sensor fails. The EAM instantly creates a work order, assigns it to the on-call facilities technician, and sends them the door's full maintenance history. The tech shows up with the right parts and tools, fixing it in a single visit. This efficiency prevents a major operational delay, avoids a pricey emergency call-out, and ensures crews can respond without a hitch.

Predictive and Preventive Maintenance Scheduling

This is where EAM gets really smart, shifting you from a reactive "break-fix" cycle to a proactive, forward-thinking strategy. Instead of waiting for things to fail, you use data to get ahead of problems.

- Preventive maintenance is based on a schedule, like changing the oil in a vehicle every 5,000 miles.

- Predictive maintenance uses real-time sensor data (like heat or vibration) to forecast exactly when a failure is likely to happen.

This approach is a total game-changer for reliability. It’s shocking, but some research shows that about 15% of organizations are still stuck in a purely reactive mode, only fixing things after they break. That's a recipe for high costs and excessive downtime. You can dig into more current enterprise asset management trends to see how far behind that puts them.

Practical Money-Saving Example:

A factory uses IoT sensors on a critical conveyor motor. The EAM detects a tiny increase in vibration that, based on historical data, precedes motor failure by about two weeks. Instead of a sudden breakdown that costs $10,000 an hour in lost production, the system schedules a routine $500 motor replacement during the next planned maintenance window. A potential catastrophe becomes a cheap, simple fix.

MRO Inventory Management

You can't fix anything if you don't have the parts. MRO (Maintenance, Repair, and Operations) inventory management is the piece that ensures you have what you need on hand without tying up a ton of cash in overstocked parts.

Think of this component as your organization's smart storeroom. It knows what you have, where it is, how fast you use it, and when to order more—often automatically.

Practical Money-Saving Example:

A public works crew needs a specific hydraulic fitting to repair a snowplow. Instead of a technician wasting an hour digging through a messy stockroom, the EAM shows them the exact bin location and current quantity on their phone. Better yet, the system noticed that stock was low last week and automatically placed an order, preventing a stockout and avoiding a $100 overnight shipping fee for an emergency part.

How EAM Directly Translates to Cost Savings and Efficiency

Knowing the theory behind Enterprise Asset Management is a good start, but where the rubber really meets the road is in dollars saved and hours reclaimed. This is the point where strategic oversight hits the bottom line, turning abstract data into real financial and operational wins.

A well-oiled EAM system isn't just another piece of software; it's an economic engine.

The core idea is simple: stop spending reactively and start investing proactively. Instead of paying a premium for emergency repairs and overnight parts, EAM lets you schedule maintenance during planned downtime when it's far more cost-effective. This forward-thinking approach has been proven to slash unplanned equipment downtime by up to 50%, directly saving revenue that would otherwise just vanish.

This shift sends ripples of savings across the entire organization, from the shop floor right up to the finance department.

Slashing Downtime and Extending Asset Lifespan

Unplanned downtime is a silent killer of profitability. Every single minute a critical asset is offline, you're not just losing production—you're paying staff who can't work and potentially facing penalties for missed deadlines. EAM tackles this problem head-on with predictive alerts.

By analyzing performance trends and sensor data, the system can flag a piece of equipment for service weeks before it actually fails. This simple act of prevention means a $500 scheduled repair takes the place of a $15,000 catastrophic failure and all the chaos that comes with it. It’s the difference between a routine check-up and emergency surgery.

On top of that, consistent, data-driven maintenance extends the functional life of your high-value assets. Good upkeep can add years of productive life to machinery, vehicles, and facilities, pushing those massive capital expenditures further down the road. It's not uncommon for organizations to see the lifespan of their critical assets extended by 20% or more.

Optimizing Inventory and Reducing Carrying Costs

Spare parts are a classic Goldilocks problem—too many ties up cash, and too few can bring operations to a screeching halt. The MRO inventory module in an EAM system gets rid of the guesswork. It gives you a crystal-clear view of what parts you have, where they are, and how fast you're using them.

This data-first approach allows you to ditch the old "just-in-case" inventory model for a much leaner "just-in-time" one. By automatically reordering parts based on actual usage, you stop overstocking items that just collect dust on a shelf. Trimming down that excess inventory directly lowers carrying costs—the money you spend on storage, insurance, and obsolescence—freeing up a significant amount of capital.

An EAM system transforms your storeroom from a static cost center into a dynamic, efficient component of your maintenance strategy, ensuring parts are available precisely when needed without wasting budget.

A major goal of EAM is to optimize the entire asset lifecycle. You can dig deeper into other strategies for reducing the total cost of ownership to see just how critical maintenance and upkeep really are.

A Practical Example of EAM Driving ROI

The real impact of EAM becomes obvious when you look at a real-world scenario. Let's take a large public transit authority responsible for a fleet of over 500 buses.

- The Challenge: They were getting hammered by rising fuel costs, frequent tire wear, and unpredictable breakdowns that were blowing up their budget and causing constant service disruptions.

- The EAM Solution: They put an EAM system in place to track every single aspect of their fleet's performance—fuel consumption, mileage, tire pressure, and engine data for each bus.

- Actionable Insights: The EAM analytics quickly found some interesting patterns. Buses running on certain hilly routes were experiencing 30% faster brake wear. The system also identified that rapid acceleration from drivers was tanking fuel efficiency by 15%.

Armed with this data, the authority changed its maintenance schedules to be based on route difficulty, not just mileage. They also rolled out targeted driver training programs. The result? A multi-million-dollar annual saving across the fleet, improved rider safety, and more reliable service—a perfect picture of EAM delivering a measurable, real-world ROI.

Understanding the Critical Difference Between EAM and CMMS

A lot of organizations get tripped up trying to figure out the difference between Enterprise Asset Management (EAM) and a Computerized Maintenance Management System (CMMS). On the surface, they sound alike—both deal with keeping equipment in good shape—but their scope and purpose are worlds apart. Nailing this distinction is the first step to picking the right system for what you actually need to do.

Let's try a simple analogy. Think of a CMMS as a specialized toolkit for a car mechanic. Its entire purpose is operational: scheduling oil changes, tracking repair jobs, and making sure you have the right spare parts on hand. It's fantastic for the day-to-day work of keeping a car running.

An EAM, on the other hand, is the entire dealership. It tracks the vehicle's whole story, right from the moment it was ordered from the factory and financed, through every service appointment and performance metric, all the way to calculating its trade-in value years later. EAM looks at the big picture, the financial and strategic life of the asset, not just its mechanical health.

Scope and Strategic Focus

A CMMS is all about tactics. Its main job is to streamline maintenance work to keep assets up and running as much as possible. It’s built for managing work orders, scheduling preventive maintenance, and keeping the parts inventory in check. It’s the "how and when" of maintenance.

EAM is strategic. While it absolutely includes all the maintenance functions of a CMMS, its view is much wider, covering the entire asset lifecycle. It helps answer bigger questions like "why are we spending so much on this asset?" and "what if we replaced it instead of repairing it again?" This is where you get the tools to make smarter financial decisions.

An EAM system gives you a holistic, financial view of an asset's total cost of ownership, turning a simple maintenance log into a powerful business intelligence tool.

This strategic oversight is essential for any organization with a lot of expensive equipment. In sectors like energy, transportation, and emergency services, where you’re managing huge and complex asset portfolios, a good EAM isn't a luxury—it's a necessity. The market reflects this, with projections showing the large enterprise segment growing at a CAGR of over 8% from 2025 to 2034. You can dig into more data on the growth of the enterprise asset management market to see how these trends are playing out.

EAM vs. CMMS: A Head-to-Head Comparison

To make the differences really clear, let's put them side-by-side. This table shows how EAM offers a much broader, more financially-driven perspective on your assets.

| Feature | CMMS (Computerized Maintenance Management System) | EAM (Enterprise Asset Management) |

|---|---|---|

| Primary Goal | Optimize maintenance operations and asset uptime. | Maximize the value of an asset over its entire lifecycle. |

| Main Function | Maintenance scheduling, work order management, and MRO inventory. | Asset lifecycle management, including finance, procurement, and compliance. |

| Typical Users | Maintenance managers, technicians, and operations staff. | All of the above, plus finance teams, procurement managers, and executives. |

| Financial Scope | Tracks maintenance costs and parts expenses. | Tracks total cost of ownership, including depreciation, energy use, and disposal value. |

Here's where the rubber meets the road. A CMMS will tell a fire department that an engine has had three major pump repairs in six months and will efficiently schedule the fixes. An EAM, however, flags that the engine's total cost of ownership (factoring in repairs, fuel, and downtime) now exceeds the cost of a newer, more reliable model.

That insight triggers a strategic decision to replace the vehicle, saving the department thousands in the long run and improving crew safety. That's the core difference: a CMMS helps you fix things right, while an EAM helps you make the right financial decisions about your assets from day one to retirement.

How Emergency Services Use EAM for Mission-Critical Reliability

In most lines of work, when a piece of equipment fails, it's an expensive headache. For first responders, it can be a matter of life and death. This is where the whole idea of enterprise asset management stops being a business buzzword and becomes a mission-critical necessity. For the folks on the front lines, reliable gear isn't just a nice-to-have; it's the foundation of public safety.

When a call drops, there's zero time to second-guess if the ambulance will start or if the defibrillator has a full charge. EAM is the system that ensures every single asset, from a massive ladder truck down to a handheld radio, is always ready to go. Failure is just not an option.

Managing a Fleet of Life-Saving Assets

Think about a typical municipal fire department. They're managing a complex fleet of engines, ladder trucks, and ambulances. Each one of those vehicles is basically a container for hundreds of other critical assets—hydraulic pumps, breathing gear, medical supplies, you name it. An EAM system is like the central nervous system for this whole operation.

Instead of clunky paper logs or a mess of spreadsheets, every asset gets tracked digitally. This opens the door to automated, proactive maintenance that can head off catastrophic failures before they ever have a chance to happen.

- Vehicle Readiness: The EAM can schedule preventive maintenance for an engine based on actual engine hours and pump usage, not just the number on the odometer. This means the parts that work the hardest get the attention they need, right when they need it.

- Equipment Calibration: It can automatically flag a batch of defibrillators for calibration two weeks before their certification is up, creating a work order and making sure they are always compliant and ready to use.

- Supply Management: The system keeps an eye on the expiration dates for critical medications and supplies on an ambulance. When something is about to expire, it shoots off an alert to restock, so a paramedic never has to discover a useless item in the middle of a call.

Practical Money-Saving Example: A sensor on a fire engine's hydraulic pump picks up a tiny pressure change. The EAM, using past data, flags this as an early sign of seal failure. It schedules a $300 proactive fix during the engine's next scheduled downtime. This simple action prevents a full-blown pump failure during a fire, which would not only take a $1 million piece of equipment out of commission but also require a $10,000 emergency repair.

Integrating EAM with Live Dispatch Operations

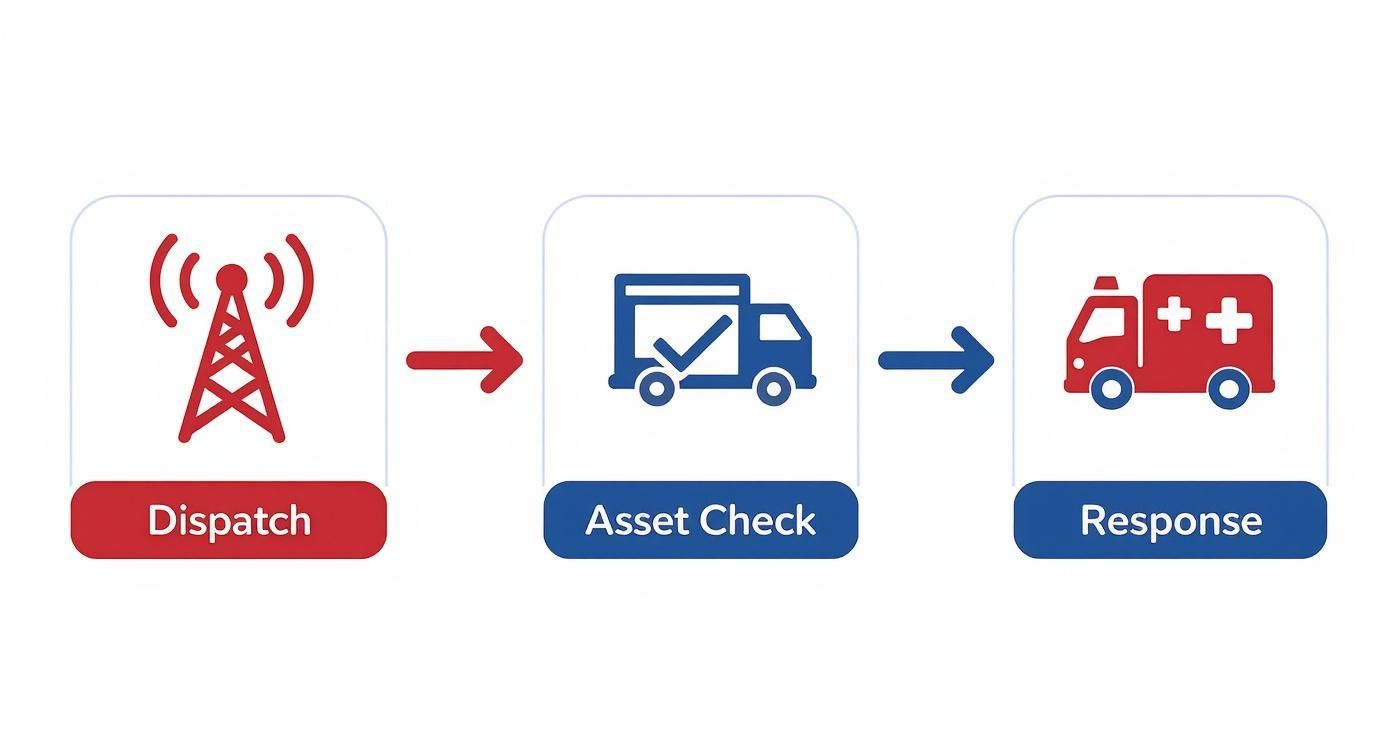

Where EAM really shows its power in emergency services is when it's tied directly into dispatch systems. This is the bridge between managing your gear and responding to a live emergency, and it can save precious minutes when it counts the most. It gives dispatchers a real-time dashboard of exactly what's ready to roll.

When a 911 call comes in, the dispatcher doesn't just see a map of available units. They see a map of fully operational units. An ambulance that's in the shop for a brake job is automatically grayed out in the dispatch system.

This smooth flow of information makes sure that only reliable, ready-to-go vehicles and crews are sent out. This is the kind of capability that's central to organizations like the team you can read about at Resgrid, and it's what turns EAM from a simple maintenance tool into a life-saving command system.

This integration delivers huge value by:

- Reducing Response Times: By getting rid of the risk of sending a unit that's out of service, the system ensures the closest and most prepared team is sent right away.

- Improving Patient Outcomes: Getting a fully stocked ambulance on scene just a few minutes faster can completely change the outcome for someone in cardiac arrest.

- Lowering Liability Risks: Having a clear, documented record that every dispatched asset was certified, maintained, and fully operational is a powerful defense against potential liability claims for the municipality.

Building Your First EAM Implementation Roadmap

Jumping into enterprise asset management can feel like a massive project, but a solid roadmap turns it from an overwhelming task into a clear, step-by-step process. A structured approach isn't just about a smoother rollout; it’s about setting yourself up to see real cost savings and operational wins right from the start.

This isn't just a software installation. It's about fundamentally shifting your organization’s mindset—moving from reactive, break-fix cycles to proactive, strategic oversight of your most important assets. The goal is to build a system that quickly pays for itself through less downtime and smarter operations.

Phase 1: Asset Discovery and Auditing

First things first: you need to know exactly what you have. You can't manage what you don't measure. This first phase is all about a comprehensive audit of all your physical assets—everything from vehicles and heavy equipment to critical IT hardware and station facilities.

For each asset, you'll need to gather all the key data points: its age, current condition, purchase price, and any maintenance history you have on file. This initial inventory becomes the foundational dataset your EAM system will use to generate insights, making it arguably the most critical phase of the entire implementation.

Phase 2: Defining Success Metrics and KPIs

Next up, you have to define what success actually looks like for your team. Vague goals like "improving efficiency" are not going to cut it here. You need to establish clear, measurable Key Performance Indicators (KPIs) that are directly tied to your organization's objectives.

Good KPIs give you a benchmark to measure your return on investment. You should think about tracking metrics like:

- Reduction in Unplanned Downtime: Aim for a specific number, like a 15% decrease in the first year.

- Maintenance Cost Per Asset: Track this to finally pinpoint those high-cost, problematic pieces of equipment.

- MRO Inventory Turnover: Improving this rate means you reduce carrying costs and free up capital that can be used elsewhere.

- Asset Lifespan Extension: Measure how proactive maintenance is extending the useful life of your most valuable assets.

The visual below shows how an EAM system fits into a real-time operational flow, connecting the dispatch center with the actual readiness of assets on the ground.

This workflow is a perfect example of how an integrated EAM ensures that only fully operational units are sent out, which saves critical time and prevents failed responses due to equipment issues.

Phase 3: Phased Implementation and Software Selection

With your assets cataloged and goals defined, you're ready to pick your software and plan the rollout. My advice? Avoid a "big bang" approach where you try to implement everything at once. It’s a recipe for headaches. Instead, go with a phased implementation.

Actionable Money-Saving Insight: Start with your most critical or problematic asset class first. By tackling a major pain point early on—like the vehicle fleet that’s always in the shop—you create a powerful case study. This early win helps secure buy-in from leadership and builds momentum for the full rollout.

When choosing software, look for a solution that can grow with you and integrate with the systems you already use. For teams that need powerful features without a complicated setup, it's worth exploring platforms where you can get direct support and guidance for your implementation.

Phase 4: Team Training and Adoption

Finally, you have to focus on your people. The best EAM system in the world is completely useless if your team doesn't know how to use it or, worse, doesn't understand why they should. Make sure you provide comprehensive training that goes beyond just pointing and clicking.

Explain the "why" behind the new system. Show your technicians and managers how it will make their jobs easier and the organization as a whole more resilient. Fostering this understanding is the real key to successful adoption and unlocking the full cost-saving potential of what enterprise asset management can offer.

Common Questions We Hear About EAM

If you're digging into enterprise asset management, you've probably got some questions. It's a big topic, and it's easy to get lost in the details. Let's clear up a few of the most common things people ask.

What's The Real Difference Between EAM And ERP?

This one comes up a lot. While both EAM and Enterprise Resource Planning (ERP) systems are workhorses for a business, they have very different jobs. Think of an ERP as the company's central nervous system—it handles core operations like finance, HR, and the supply chain. It sees the big picture.

An EAM, on the other hand, is laser-focused on one thing: the complete lifecycle of your physical assets. The real magic happens when they talk to each other. A modern EAM feeds crucial data—like maintenance spending and asset depreciation—right into the ERP.

Here’s a practical example: Your EAM flags that a specific ambulance's repair costs have officially exceeded its value. That data flows to the ERP, which then uses it for accurate financial forecasting. Just like that, you can budget for a replacement instead of getting hit with a massive, unexpected expense down the road.

How Long Does It Actually Take To Implement An EAM?

Honestly, it varies wildly. The timeline really depends on the size of your organization, how many assets you're tracking, and—this is a big one—the quality of your existing data. A small-scale rollout for a single station might only take a few months.

But a full, enterprise-wide implementation for a large county or a major corporation? That could easily take over a year.

The smartest way to tackle this is with a phased approach. Start with one critical area, like your primary response fleet. This lets you manage the complexity, get some early wins on the board, and build momentum for the rest of the rollout. It’s the best way to avoid going over budget and prove the system's value quickly.

Can A Small Department Actually Benefit From EAM?

Absolutely. It used to be that EAM was a tool exclusively for massive corporations with deep pockets. But the rise of scalable, cloud-based solutions has put it well within reach for small and medium-sized organizations. In fact, the benefits can be even more dramatic for smaller operations.

For a small volunteer fire department, the failure of a single pumper truck can shut down their ability to respond entirely. The proactive maintenance and lifecycle tracking in an EAM can provide a massive return on a relatively small investment.

Here’s how that plays out: A small EMS agency can use an EAM to monitor the performance of its primary cardiac monitor. By catching a sensor anomaly, they can schedule a $200 predictive repair. That simple action helps them avoid a catastrophic failure during a call, which could have cost $20,000 in emergency repairs and lost service revenue—an expense that could cripple a small agency.

An effective EAM strategy is the foundation, but it becomes truly powerful when integrated with a solid dispatch and coordination platform. This ensures your most critical assets are always ready for action when the call comes in. Resgrid provides the tools to manage your personnel and operations seamlessly, making sure the right people are dispatched with the right, fully-operational equipment every single time. Learn more at https://resgrid.com.