The Ultimate Fire Inspection Checklist: 10 Critical Points for 2026

A fire inspection is more than a regulatory requirement; it's a fundamental process that protects lives, property, and operational continuity. Many organizations, however, treat their fire inspection checklist as a mere compliance task, a series of boxes to tick before an official visit. This approach overlooks a powerful opportunity to transition from reactive scrambling to proactive prevention, unlocking significant cost savings and building a more resilient facility. A poorly managed inspection process can lead to overlooked hazards, hefty fines for non-compliance, and, most critically, catastrophic failures during an emergency.

This guide reframes the checklist from a simple form into a strategic, lifesaving tool. We will dissect the 10 most critical inspection points, providing actionable insights that go beyond basic compliance. You will learn how a meticulously maintained and documented inspection process can directly lead to lower insurance premiums by demonstrating a lower risk profile to underwriters. Furthermore, by identifying and rectifying issues early, you can avoid the exorbitant costs associated with emergency repairs, business downtime, and regulatory penalties.

We'll cover everything from sprinkler systems and egress pathways to electrical hazard assessments and flammable materials management. To ensure your fire inspection checklist remains current and effective, it's essential to stay informed about regulatory changes, such as the updates outlined in the guide on Understanding the 2026 Fire Safety Codes. By implementing the strategies detailed in the following sections, you will not only satisfy regulatory bodies but also create a safer environment and a more financially sound operation.

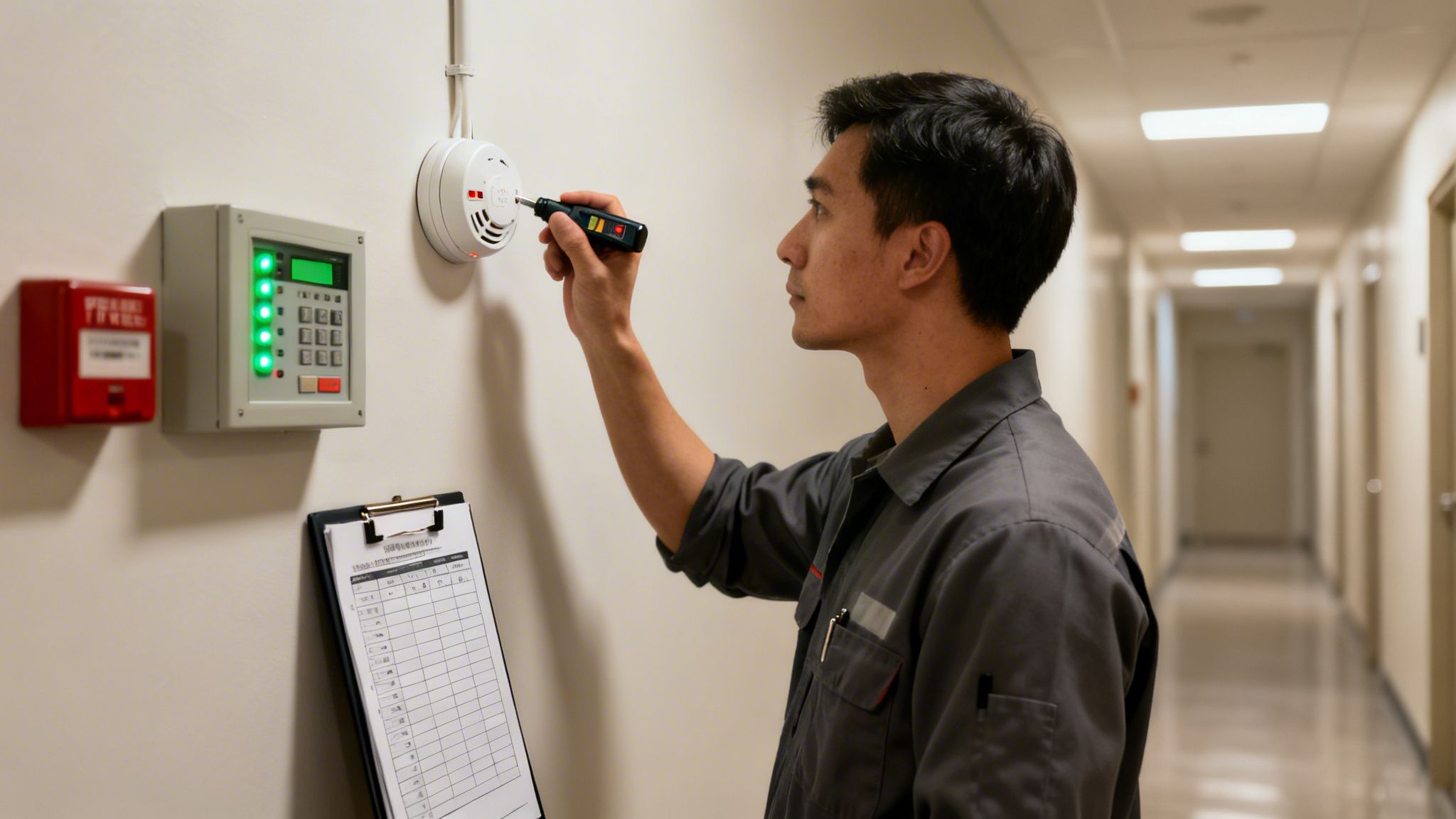

1. Fire Alarm System Testing and Maintenance

A functional fire alarm system is your first line of defense, providing the critical early warning needed for safe evacuation and rapid emergency response. This part of your fire inspection checklist confirms that every component, from smoke detectors and pull stations to notification appliances like horns and strobes, operates exactly as designed. The goal is to verify not just compliance but true operational readiness, ensuring the system can reliably detect a fire, alert occupants, and notify the proper authorities without failure.

This goes beyond the mandatory annual certification by a licensed technician. It involves regular, in-house checks of the main alarm control panel for any trouble signals, ensuring battery backups are charged, and confirming that all zones are active and properly labeled. A well-maintained system prevents costly false alarms, which can lead to municipal fines and desensitize occupants to real emergencies.

Real-World Application and Benefits

Practical Example: A large hotel experienced frequent false alarms from a detector near a steam room, leading to costly fire department call-out fees and guest dissatisfaction. During a detailed inspection, they identified that a simple heat detector was installed instead of a more appropriate (and slightly more expensive) combination photoelectric/heat detector designed for such environments.

Money-Saving Insight: Making this small, targeted upgrade eliminated the false alarms, saving them thousands annually in municipal fines and preventing the need for disruptive, non-emergency service calls. Proactive system maintenance avoids catastrophic equipment loss and operational downtime, saving millions in potential damages and lost revenue.

Key Insight: Regular testing turns your fire alarm system from a passive, compliance-based asset into an active, life-saving tool. Early detection directly correlates to reduced property damage and, most importantly, prevents injuries and fatalities.

Actionable Implementation Tips

- Go Beyond Annual Testing: Implement quarterly self-inspections to check panel status, test batteries, and perform visual checks of detectors and notification devices. This helps catch issues between professional service visits.

- Digitize Maintenance Logs: Use a platform like Resgrid to maintain detailed, cloud-based logs of all tests, inspections, and service calls. This provides instant access to system history for technicians, inspectors, and first responders during an emergency, saving valuable diagnostic time and money during service calls.

- Train Your Team: Ensure multiple staff members on each shift know how to identify alarm panel signals (alarm, trouble, supervisory) and understand the basic procedure for silencing and resetting the system after an event is confirmed as a false alarm.

- Build a Contractor Relationship: Don't just hire any certified company. Establish a relationship with a reliable fire alarm contractor for priority service, which is crucial for minimizing downtime when a critical repair is needed.

2. Emergency Exit Routes and Egress Pathway Inspection

Clear and accessible emergency exit routes are non-negotiable for life safety, serving as the primary means for occupants to escape a fire. This crucial element of your fire inspection checklist ensures that all egress pathways, from individual workstations to the final exit discharge, are unobstructed, properly marked, and illuminated. The objective is to guarantee a swift, intuitive, and safe evacuation, confirming that nothing impedes the flow of people moving toward safety.

This process involves more than just checking that exit signs are lit. It requires a comprehensive walk-through to verify that corridors, stairwells, and doorways are free from storage, equipment, and debris. Inspectors also confirm that all exit doors are unlocked from the inside and open easily without special knowledge or effort, a fundamental requirement for preventing entrapment during a high-stress emergency.

Real-World Application and Benefits

Practical Example: A busy warehouse consistently received minor citations for pallets stored too close to an emergency exit. The operations manager believed the area was the most efficient staging point.

Money-Saving Insight: By conducting a cost analysis, they realized the recurring fines and increased insurance premiums from the repeated violations were higher than the perceived efficiency gain. They reconfigured the staging area, eliminating the fines and demonstrating a lower risk profile to their insurer, which contributed to a more favorable policy renewal rate. This proactive measure not only ensures NFPA compliance but also significantly reduces the risk of injuries and potential liability.

Key Insight: An egress path is a complete system, not just a door. Ensuring its integrity from start to finish transforms a building from a potential hazard into a safe haven, directly protecting human lives and minimizing operational chaos during an incident.

Actionable Implementation Tips

- Conduct Monthly Pathway Audits: Designate a team member to walk all egress routes monthly. This simple, low-cost practice prevents the gradual accumulation of obstructions like boxes, furniture, or equipment that can block paths over time.

- Map Exits and Assembly Points Digitally: Use a platform like Resgrid to create and store digital facility maps that clearly mark all exit routes, fire extinguisher locations, and outdoor assembly areas. This provides first responders with immediate situational awareness, potentially reducing the time and resources needed to control an incident, which can lower the overall cost of damages.

- Train for Blocked Routes: Don't just drill for primary exits. Regularly conduct evacuation drills that simulate a blocked primary route, forcing staff to use and become familiar with secondary and tertiary egress paths.

- Enhance Visibility: Apply high-visibility, photoluminescent tape to the frames of exit doors and along the floor of egress pathways. This low-cost enhancement provides critical visual guidance in smoky or low-light conditions, speeding up evacuation and preventing disorientation.

3. Sprinkler System Inspection and Water Supply Verification

Automatic sprinkler systems are arguably the single most effective method for controlling or extinguishing fires in their early stages, often before the fire department arrives. This crucial section of your fire inspection checklist ensures the entire system is primed for immediate action. It involves verifying that sprinkler heads are unobstructed, water supply pressure is adequate, control valves are in the correct open position, and the system complies with NFPA 13 standards for operational readiness.

The inspection goes beyond a simple visual check. It confirms that the system can deliver the required volume and pressure of water to suppress a fire effectively. This includes testing flow switches, tamper switches on control valves, and the fire pump, ensuring every component will function seamlessly during an emergency. Proper maintenance prevents system failures that could lead to catastrophic property loss and business interruption.

Real-World Application and Benefits

Practical Example: A large warehouse that stores high-value inventory noticed a slow, persistent drip from a single sprinkler head joint. They considered delaying the repair to avoid system downtime.

Money-Saving Insight: Instead, they scheduled an immediate, off-hours repair with their contractor. The cost was minimal. Months later, they learned a similar facility ignored a small leak, which eventually led to a catastrophic pipe failure, flooding their inventory and causing over $500,000 in damages and lost business. The proactive repair saved them from a devastating financial loss and a massive insurance claim.

Key Insight: A sprinkler system is a 24/7 firefighter. Verifying its readiness and water supply ensures it can perform its job, drastically minimizing fire, smoke, and water damage by activating precisely where and when needed.

Actionable Implementation Tips

- Schedule Quarterly Visual Checks: Don't wait for the annual professional service. Have your staff perform quarterly visual inspections to check for damaged or painted sprinkler heads, ensure gauges show proper pressure, and confirm nothing is stored within 18 inches of a sprinkler head.

- Keep Spare Heads On-Site: Maintain a stock of spare sprinkler heads (and the appropriate wrench) for each type used in your facility. This allows for immediate replacement by a qualified technician, minimizing system downtime and costly emergency call-out fees after an accidental activation or damage.

- Digitize System Maps and Logs: Use a platform like Resgrid to store digital maps of all sprinkler zones, valve locations, and riser rooms. Logging all inspections provides a clear history for compliance and faster troubleshooting, reducing technician time on site.

- Pre-Plan System Testing: Always notify building occupants and your alarm monitoring company before conducting water flow tests. This simple step prevents unnecessary emergency responses, building evacuations, and potential fines for false alarms.

4. Fire Extinguisher Accessibility, Maintenance, and Training

Portable fire extinguishers are the essential first-response tool for your personnel, empowering them to control small, incipient fires before they escalate. This crucial part of your fire inspection checklist ensures these life-saving devices are accessible, properly maintained, and that your staff is confident in using them. The objective is to verify that the right type of extinguisher is in the right place, fully charged, and unobstructed, transforming a passive safety device into an active, immediate defense.

This process involves more than just a glance at the pressure gauge during a walkthrough. It requires documented monthly visual checks, professional annual servicing, and hydrostatic testing at required intervals. A well-managed extinguisher program not only meets NFPA 10 standards but also prevents a minor incident, like an overheated piece of equipment, from becoming a full-blown emergency that triggers costly sprinkler deployment and significant operational downtime.

Real-World Application and Benefits

Practical Example: A commercial kitchen had a grease fire ignite on a cooktop. An employee, trained in both fire classifications and proper extinguisher use, immediately grabbed the nearby Class K extinguisher.

Money-Saving Insight: By correctly using the PASS technique, they suppressed the fire in seconds. This quick action prevented the fire from reaching the kitchen's expensive suppression system, which would have required a costly system recharge and professional cleaning of the entire kitchen, shutting down operations for days. The small investment in training saved them tens of thousands in direct costs and lost revenue.

Key Insight: A fire extinguisher is only effective in the hands of a trained and confident user. Regular training and proper maintenance turn a compliance requirement into a powerful tool for immediate risk mitigation and business continuity.

Actionable Implementation Tips

- Conduct Monthly Quick Checks: Designate a staff member to perform and log monthly visual inspections of every extinguisher. Check for accessibility, visible damage, a charged pressure gauge, and an intact tamper seal.

- Create a Digital Inventory: Use a tool to manage your extinguisher inventory, tracking locations, types (A, B, C, D, K), and service dates. With the right emergency management apps, you can set automated reminders for servicing and testing, avoiding costly last-minute rush fees or fines for expired units.

- Provide Hands-On Training: Go beyond videos. Partner with a fire safety company to conduct annual hands-on training where employees can practice using the PASS technique on a controlled fire. This builds muscle memory and confidence.

- Ensure Clear Visibility and Signage: Mount extinguishers correctly and ensure their locations are marked with highly visible signage. The path to every extinguisher must remain clear of obstructions like storage boxes, carts, or equipment.

5. Fire-Rated Doors, Walls, and Compartmentalization Verification

Passive fire protection, such as fire-rated doors and walls, is the silent defender of a building’s structural integrity during an emergency. This element of your fire inspection checklist focuses on compartmentalization: the strategy of containing a fire to its room of origin to protect escape routes and prevent catastrophic spread. Inspections must verify that these assemblies, whether rated for 1, 2, or 4 hours, are undamaged, properly sealed, and fully functional, ensuring the building performs as designed when it matters most.

This process involves more than just looking for a rating label. It means checking that fire doors close completely and latch securely on their own, ensuring that gaskets and intumescent seals are intact, and verifying that any penetrations for pipes or wiring are sealed with approved firestop materials. A compromised fire barrier, such as a door propped open or a hole in a rated wall, renders the entire compartmentalization strategy useless and creates a direct path for fire and toxic smoke.

Real-World Application and Benefits

Practical Example: In a multi-unit residential building, a maintenance worker drilled a hole through a fire-rated wall to run a new cable but failed to seal it with proper firestop caulk, leaving an open gap.

Money-Saving Insight: During a routine inspection, this deficiency was caught. The cost to properly seal the penetration was less than $50. If left uncorrected, a fire could have spread through that opening, leading to a multi-unit disaster, massive property damage, resident displacement, and significant legal liability. This small, proactive fix prevented millions in potential losses.

Key Insight: Active systems like sprinklers can fail, but properly maintained passive fire barriers work 24/7 without power or activation. They are a fundamental, non-negotiable layer of life safety.

Actionable Implementation Tips

- Conduct Quarterly Door Checks: Assign staff to walk through the facility quarterly and check every fire-rated door. Ensure they are not illegally propped open, obstructed, or damaged, and confirm that their self-closing mechanisms are functional.

- Map and Document Assemblies: Use a platform like Resgrid to upload facility floor plans and digitally map the locations and ratings of all fire walls and barriers. This provides invaluable intelligence to first responders, showing them where they can establish defensive positions to save property and minimize damage.

- Inspect Penetrations: During routine maintenance, inspect areas where new wiring, plumbing, or ductwork has been installed through rated walls. Verify that all penetrations are sealed with appropriate firestop caulk or devices, not just generic foam.

- Train Staff on the "Why": Educate all employees that propping a fire door open isn't just a minor rule violation; it's an action that endangers everyone in the building. Training turns every staff member into a partner in maintaining building safety.

6. Electrical Systems and Equipment Fire Hazard Assessment

Faulty electrical systems are a leading cause of devastating structural fires, often starting from issues hidden within walls, panels, or equipment. This crucial part of your fire inspection checklist focuses on proactively identifying and mitigating these invisible threats. The goal is to verify that electrical panels are accessible and not overloaded, wiring is in good condition, equipment is properly grounded, and there are no signs of overheating that could lead to arcing or insulation failure.

This assessment goes far beyond a simple visual check. It involves ensuring all modifications are up to code, circuits are clearly labeled, and advanced tools like thermographic imaging are used to detect hot spots invisible to the naked eye. Proper electrical maintenance prevents catastrophic equipment failure, ensures operational continuity, and addresses a primary ignition source before it can spark a fire.

Real-World Application and Benefits

Practical Example: A data center scheduled a routine thermographic inspection of its electrical panels. The scan revealed a circuit breaker running 40 degrees hotter than identical units nearby, indicating an imminent failure.

Money-Saving Insight: The cost to de-energize the panel and replace the faulty breaker during scheduled downtime was a few hundred dollars. If the breaker had failed under load, it could have caused an arc flash fire, destroying a server rack worth over $250,000 and causing a catastrophic, revenue-crushing data outage. This predictive maintenance directly prevented a massive financial and operational disaster.

Key Insight: Proactive electrical inspections shift your safety strategy from reactive to predictive. Identifying thermal anomalies and overloaded circuits before they fail prevents fires, protects expensive assets, and eliminates unplanned operational downtime.

Actionable Implementation Tips

- Schedule Thermographic Scans: Conduct annual thermographic inspections with a qualified electrician during periods of moderate to high electrical load to accurately identify potential failure points in panels and equipment.

- Audit Temporary Wiring: Implement a strict policy for temporary power solutions like extension cords. Inspect them monthly for damage and ensure they are never used as a permanent wiring substitute, which is a common fire code violation.

- Maintain Digital Electrical Records: Use a platform like Resgrid to log all electrical maintenance and store inspection reports. This ensures technicians have immediate access to critical system history, speeding up diagnostics and reducing billable service hours.

- Train Staff on Electrical Safety: Educate all employees to recognize signs of electrical hazards, such as flickering lights, unusual odors, or warm outlets, and to understand procedures for safely de-energizing equipment in an emergency.

7. Storage, Housekeeping, and Flammable Materials Management

While sophisticated systems are crucial, human factors like poor housekeeping and improper storage are among the leading causes of workplace fires. This part of your fire inspection checklist addresses the operational discipline required to manage flammable materials and prevent the accumulation of combustible debris. The goal is to minimize fire loads and eliminate fuel sources that could turn a minor spark into a major inferno, making it one of the most critical and frequently cited areas during an official inspection.

This inspection item verifies that flammable liquids and gases are stored in approved cabinets or designated rooms, hazardous waste is properly contained, and general clutter is kept to a minimum. It’s about creating a culture of cleanliness and safety where potential fire hazards are proactively removed before they can pose a threat. A well-managed facility is inherently safer and often more efficient.

Real-World Application and Benefits

Practical Example: A vehicle maintenance shop was cited for improperly storing oily rags in an open bin.

Money-Saving Insight: Instead of just paying the fine, they invested a few hundred dollars in proper, self-closing waste containers. This not only eliminated future fines but also significantly reduced their risk profile for spontaneous combustion fires. Their insurance agent noted this improvement during a site visit, which helped them maintain a favorable premium at renewal. The small investment in proper equipment provided a direct return by avoiding penalties and supporting lower insurance costs.

Key Insight: Excellent housekeeping is one of the most cost-effective forms of fire prevention. It costs very little to implement but offers an enormous return by reducing ignition sources and limiting the fuel available for a fire to spread.

Actionable Implementation Tips

- Implement Monthly Walkthroughs: Conduct and document monthly housekeeping inspections, using photos to highlight both compliance and areas needing improvement. This creates a visual record of progress and accountability.

- Map Your Hazards: Create detailed floor plans that clearly mark the locations of all flammable and combustible material storage areas. Make these maps accessible to staff and first responders.

- Establish Clear Standards: Don't just say "keep it clean." Define what "clean" means for each area, assign responsibility, and post the standards visibly. This removes ambiguity and improves consistency.

- Digitize Tasks and Audits: Use a platform like Resgrid to schedule and assign recurring housekeeping tasks and audits. This ensures inspections are never missed and creates a digital trail for compliance verification, which is invaluable during an official inspection and can help expedite insurance claims.

- Maintain Your SDS Library: Ensure Safety Data Sheets (SDS) for all hazardous chemicals are readily accessible, and train employees on how to read them to understand storage and handling requirements.

8. Fire Department Access, Water Supply, and External Infrastructure

Emergency response effectiveness begins before first responders even arrive on-site. This part of your fire inspection checklist ensures that fire departments have unobstructed access to your property and a reliable water supply to combat a fire. It involves verifying that fire lanes are clear and wide enough for apparatus, hydrants are accessible and functional, and external connections are properly maintained. The goal is to eliminate any physical barriers that could delay a critical emergency response when every second counts.

This crucial step assesses the external readiness of your facility. It confirms that roads can support the weight of heavy fire trucks, hydrants provide adequate water pressure as required by NFPA standards, and all fire department connections (FDCs) are clearly marked and free from obstruction. Neglecting this area can render even the best internal fire suppression systems ineffective if firefighters cannot connect to them or reach the building.

Real-World Application and Benefits

Practical Example: A large industrial park found that a delivery truck was habitually parked in a designated fire lane.

Money-Saving Insight: Instead of just repeated warnings, they installed permanent "No Parking – Fire Lane" signage and implemented a strict towing enforcement policy. Months later, a fire broke out. The clear lane allowed an aerial ladder truck to position perfectly, containing the fire to one section of the building. This prevented the fire from spreading to an adjacent area with high-value machinery, saving the company millions in potential property damage and avoiding a prolonged, business-ending shutdown. The cost of signage and enforcement was negligible compared to the loss averted.

Key Insight: Your property's exterior is the staging ground for any emergency response. Maintaining clear access and a functional water supply is as critical as any internal fire safety system, directly impacting the speed and success of firefighting operations.

Actionable Implementation Tips

- Consult Local Authorities: Contact your local fire department to confirm their specific requirements for apparatus access roads, turning radii, and hydrant spacing, as these can vary by jurisdiction.

- Keep Hydrants Clear: Maintain a three-foot clear space around all fire hydrants. Regularly trim back vegetation and ensure snow is removed promptly in the winter to keep them visible and accessible.

- Map Critical Infrastructure: Use a system like Resgrid to map all fire access routes, hydrant locations, and FDC points. Sharing this pre-plan data with first responders gives them vital intelligence before they arrive, saving them time and potentially reducing the extent of property damage. Learn more about how to enhance your operational planning with shared digital resources.

- Annual Water Supply Testing: Coordinate with your local water utility or fire department to conduct annual flow tests on your hydrants. This verifies they can provide the necessary pressure and flow (gallons per minute) required for firefighting operations.

9. Emergency Lighting, Signage, and Wayfinding Systems

When a fire causes a power outage or fills a building with smoke, normal visibility is lost in seconds. Emergency lighting and exit signage are the critical systems that cut through the chaos, illuminating the path to safety. This part of your fire inspection checklist ensures these systems are fully operational, verifying that emergency lights activate instantly, signs are visible and correctly placed, and backup power sources like batteries or generators are ready to perform. The objective is to guarantee a clear, illuminated evacuation route for everyone, even in the most disorienting conditions.

This inspection goes beyond simply checking if a light turns on. It involves confirming adequate illumination levels along the entire means of egress, ensuring exit signs are free from obstruction, and testing the duration of battery backups to meet code requirements (typically 90 minutes). A well-maintained system prevents panic and confusion, directly enabling a swift and orderly evacuation when every second counts.

Real-World Application and Benefits

Practical Example: A multi-story office building identified several failing battery units in its emergency lights during a quarterly test.

Money-Saving Insight: They replaced the faulty batteries immediately at a cost of about $40 per unit. During a subsequent power outage, the fully functional system allowed for a safe and orderly evacuation. Had they not made the repair, the darkened stairwells could have led to trips, falls, and injuries, resulting in significant worker's compensation claims and potential litigation far exceeding the cost of the replacement batteries. Proactive maintenance is a direct investment in avoiding liability.

Key Insight: Emergency lighting and signage are not just for compliance; they are active life-safety systems that function when all others fail. Their reliability is directly linked to an occupant's ability to self-evacuate safely during a high-stress emergency.

Actionable Implementation Tips

- Perform Monthly "Push-to-Test" Checks: Designate a staff member to conduct a 30-second monthly visual inspection of all emergency lights and exit signs by pressing the "test" button. This quick check verifies battery and bulb function between more intensive tests.

- Schedule and Log Annual 90-Minute Tests: Conduct an annual full-load test to ensure battery-powered units last the required 90 minutes. Meticulously document all results, including any failures and the corrective actions taken.

- Integrate with Wayfinding: Crucial for guiding occupants and complying with regulations, proper safety signage is a non-negotiable aspect of any fire safety plan. Use photoluminescent tape on stair treads and door frames in low-light areas to supplement electrical systems.

- Digitize Testing Schedules: Use a system like Resgrid to schedule and track monthly and annual tests for all lighting units. This creates an automated, auditable record that can prove due diligence to inspectors and insurance adjusters, potentially speeding up claims processes and reducing liability.

10. Special Hazards and Occupancy-Specific Fire Protection Systems

Standard fire protection is often insufficient for areas with unique or heightened risks. This section of your fire inspection checklist focuses on specialized systems designed to combat specific threats, such as clean-agent suppression in data centers or foam systems in flammable liquid storage areas. These occupancy-specific solutions are engineered to suppress a fire quickly and effectively without causing catastrophic collateral damage to sensitive equipment or reacting dangerously with hazardous materials. The goal is to verify that these critical systems are fully operational, properly certified, and ready for their specific purpose.

Inspecting these systems means going beyond a simple visual check. It requires confirming that detection and activation mechanisms are functional, suppression agent levels are correct, and all components are free from damage or obstruction. Proper maintenance ensures that in a fire event, the right agent is deployed at the right concentration, neutralizing the threat before it can escalate, protecting high-value assets, and ensuring personnel safety in high-risk environments.

Real-World Application and Benefits

Practical Example: A data center's semi-annual inspection of its FM-200 clean-agent system identified a low-pressure reading in one agent cylinder, indicating a slow leak.

Money-Saving Insight: The cost to have a technician repair the valve and top off the cylinder was approximately $1,500. If the system had discharged during a fire with insufficient agent, the fire might not have been extinguished, potentially triggering the building's main sprinkler system as a last resort. This would have caused millions of dollars in water damage to servers, leading to catastrophic data loss and business interruption. The proactive service call saved the company from an existential threat.

Key Insight: Specialized fire protection systems are not a luxury; they are a necessity for mitigating unique risks. Their proper function is the difference between a minor, contained incident and a multi-million-dollar operational and financial catastrophe.

Actionable Implementation Tips

- Document and Certify: Identify every special hazard system on-site and maintain a dedicated file with all maintenance records, testing certificates, and service reports. This is critical for both compliance and liability.

- Use Resgrid for Specialized Tracking: Program platforms like Resgrid with custom reminders for the unique inspection and certification schedules of each system (e.g., semi-annual cylinder weighing). This avoids missed deadlines and ensures you maintain the system's warranty and insurance eligibility, which can save thousands in uncovered losses.

- Train for Specific Scenarios: Personnel working in special hazard areas must be trained on the system's pre-alarm signals, proper evacuation procedures, and any manual activation or abort stations. This knowledge is crucial for their safety.

- Partner with Niche Experts: Establish a strong relationship with a contractor certified to service your specific systems (e.g., clean-agent, dry chemical, etc.). General fire protection companies may lack the necessary expertise for these complex installations.

10-Point Fire Inspection Checklist Comparison

| Item | 🔄 Implementation complexity | ⚡ Resource requirements | 📊 Expected outcomes | 💡 Ideal use cases / tips | ⭐ Key advantages |

|---|---|---|---|---|---|

| Fire Alarm System Testing and Maintenance | Moderate — annual NFPA 72 certification; periodic integration checks | Certified technicians, testing tools, service contracts, batteries, panel access | Reliable early detection; faster occupant notification; code compliance | Commercial buildings, high-rises, hospitals; schedule quarterly checks and log digitally | ⭐⭐⭐⭐ — high life-safety impact, automated alerts reduce human error |

| Emergency Exit Routes and Egress Pathway Inspection | Low–Moderate — routine walk‑throughs, signage checks | Minimal equipment; staff time for inspections and corrective actions | Clear evacuation paths; reduced evacuation time and liability | Offices, schools, assembly venues; monthly walk‑throughs and map exits in Resgrid | ⭐⭐⭐⭐ — cost‑effective risk reduction; prevents bottlenecks |

| Sprinkler System Inspection and Water Supply Verification | High — annual hydro tests, pressure verification, zone testing per NFPA 13 | Certified technicians, water supply access, valves, backflow testing, spare parts | Substantial reduction in fire spread and fatalities; improved suppression reliability | Multi‑story buildings, warehouses, manufacturing; quarterly visual checks and maintain supply reports | ⭐⭐⭐⭐⭐ — most effective active suppression; major property-loss reduction |

| Fire Extinguisher Accessibility, Maintenance, and Training | Low — monthly visual checks plus annual servicing and hydrostatic testing | Extinguishers, inspection tags, certified servicing, training sessions | Quick initial response to small fires; empowers staff; compliance | Kitchens, labs, maintenance areas; train on PASS and log in Resgrid | ⭐⭐⭐ — immediate small‑fire control; low cost but limited for large fires |

| Fire‑Rated Doors, Walls, and Compartmentalization Verification | Moderate — inspection of assemblies, seals, and closing mechanisms | Qualified inspectors, replacement seals/doors, caulking materials, documentation | Limits fire/smoke spread; protects escape routes; increases containment time | Hospitals, data centers, multi‑unit residential; map compartments and enforce no‑prop policy | ⭐⭐⭐⭐ — strong passive protection; critical for containment strategies |

| Electrical Systems and Equipment Fire Hazard Assessment | Moderate–High — thermography, code compliance checks, load studies | Licensed electricians, thermographic equipment, possible shutdowns for repairs | Identifies hot spots before failure; reduces electrical fire risk and downtime | Industrial sites, data centers, older buildings; schedule thermography during moderate loads | ⭐⭐⭐⭐ — preventive detection of hidden hazards; reduces catastrophic failures |

| Storage, Housekeeping, and Flammable Materials Management | Low–Moderate — procedural controls and periodic audits | Storage cabinets, labeling, SDS management, staff training | Reduces fire load and chemical risk; prevents incompatible storage incidents | Manufacturing, labs, maintenance shops; implement daily tidy routines and SDS access | ⭐⭐⭐⭐ — high risk reduction for low cost; prevents many common violations |

| Fire Department Access, Water Supply, and External Infrastructure | High — site work, road/hydrant compliance, coordination with authorities | Civil works, hydrant installation/testing, liaison with utility and fire dept | Ensures apparatus access and sufficient water for operations | Industrial parks, hospitals, remote facilities; map access and test water annually | ⭐⭐⭐⭐ — enables effective external suppression and safe operations |

| Emergency Lighting, Signage, and Wayfinding Systems | Low–Moderate — battery/generator testing, illumination verification | Emergency fixtures, batteries/generator maintenance, testing tools | Maintains visibility during outages; reduces panic and evacuation time | Underground spaces, public assembly, healthcare; monthly checks and battery load tests | ⭐⭐⭐ — critical for safe egress; relatively low cost but maintenance‑dependent |

| Special Hazards and Occupancy‑Specific Fire Protection Systems | High — specialized system testing, agent handling, certification | Specialty contractors, recharge capabilities, environmental controls, documentation | Protects sensitive assets without water damage; tailored suppression effectiveness | Data centers, aircraft hangars, chemical plants, battery facilities; track certifications in Resgrid | ⭐⭐⭐⭐ — protects valuable/sensitive assets; costly but necessary for specialty risks |

From Checklist to Culture: Integrating Your Fire Safety Plan

Navigating the extensive landscape of fire safety can feel overwhelming. Throughout this guide, we have dissected the essential components of a comprehensive fire inspection checklist, moving from the building's exterior and fire department access points to the intricate details of sprinkler systems, electrical hazards, and emergency egress routes. We have examined the critical roles of fire-rated compartmentalization, the proper maintenance of fire extinguishers, and the specific needs of special hazard areas. The goal was not merely to list items, but to provide a structured, actionable framework for proactive safety management.

However, the most meticulously crafted checklist is only a starting point. Its true power is unlocked when it transcends a periodic, compliance-driven task and becomes an integrated part of your organization's operational DNA. The ultimate objective is to shift from a reactive mindset of "passing an inspection" to a proactive culture of "maintaining constant readiness." This cultural shift is where genuine safety, resilience, and long-term cost savings are forged.

Beyond the Clipboard: The Value of Proactive Integration

A static, paper-based fire inspection checklist serves a purpose, but it often creates information silos and administrative bottlenecks. Findings are manually recorded, corrective actions are tracked in separate spreadsheets, and historical data is filed away, rarely contributing to a broader understanding of risk trends. This approach is not only inefficient but can be costly. A missed follow-up on a faulty emergency light or an obstructed egress path can lead to failed inspections, fines, and, most critically, a catastrophic failure during a real emergency.

The true value lies in transforming your checklist from a simple document into a dynamic, living system. When inspection data is centralized and accessible, it empowers you to:

- Identify Recurring Issues: Are the same fire doors consistently found propped open? Is a particular area repeatedly flagged for poor housekeeping? Digital tracking reveals patterns that a paper trail might obscure, allowing you to address root causes through targeted training or process changes.

- Streamline Corrective Actions: Instead of a handwritten note getting lost, a digital system can automatically assign a corrective task to the maintenance department, set a deadline, and send reminders until the issue is resolved and documented. This closes the loop on deficiencies, ensuring nothing falls through the cracks.

- Enhance First Responder Awareness: Imagine first responders arriving on the scene already knowing the location of your fire department connection, the status of your sprinkler system, and the presence of hazardous materials. Integrating your inspection data into a pre-incident plan provides this critical intelligence, saving precious seconds and improving operational safety for everyone involved.

Actionable Next Steps to Build Your Safety Culture

Mastering your fire safety protocol is an ongoing process, not a one-time event. The difference between a compliant facility and a truly safe one is the commitment to continuous improvement. By embracing the principles outlined in this guide and leveraging modern tools, you build a resilient organization that not only protects its assets but, more importantly, its people. This commitment to a robust safety culture is the ultimate return on investment, mitigating risks that are far more costly than any preventative measure.

A checklist ensures you look; a culture of safety ensures you see. It's the active, ongoing engagement with these principles that transforms a list of requirements into a shield of protection.

By moving beyond simple compliance and fostering a deeply ingrained culture of safety, you are not just ticking boxes on a fire inspection checklist. You are building a foundation of preparedness that protects your most valuable assets: your people, your property, and your future.

Ready to elevate your fire inspection process from a manual checklist to a dynamic, automated system? Resgrid, LLC provides a powerful platform to manage inspections, track corrective actions, and integrate critical data into pre-incident plans for first responders. Discover how our system can streamline your workflow and enhance safety by visiting us at Resgrid, LLC today.