A Guide to Assets Inventory management

So, what exactly is assets inventory management? Think of it as the grand, unified strategy for keeping tabs on everything your organization owns—from the big-ticket equipment that lasts for years to the everyday consumable supplies. It’s about merging two crucial jobs, asset management and inventory control, into one seamless system. When you do this, you get a complete, honest picture of all your operational resources.

Defining Assets Inventory Management

Let’s imagine you’re running a busy first response unit. You have your fire engines and ambulances—these are your long-term, high-value assets. Then you have your medical supplies, bandages, and spare parts for the trucks—that’s your inventory.

Managing these two lists in separate silos is just asking for trouble. What happens when a critical pump on the engine fails during a call, but you discover the necessary spare part isn't actually in stock? The whole operation can grind to a halt, putting lives and property at risk.

Assets inventory management closes that dangerous gap. It’s a holistic approach that gives you a single source of truth for every physical thing your team relies on. It doesn't matter if it's a vehicle with a ten-year service life or a box of bolts used for a single repair—it’s all tracked in one place. This unified view isn't just a nice-to-have; it's essential for operational readiness and financial stability.

Without it, organizations often fall victim to "ghost assets." These are items that exist on your books and in your budget but are physically missing, lost, or broken. For example, a company might pay insurance premiums on a fleet of 50 laptops when, in reality, five were stolen or broken months ago. This is a direct financial drain that an integrated system eliminates.

The Financial Impact of an Integrated System

Getting these systems to talk to each other does more than just keep your lists tidy; it directly hits your bottom line. When you integrate these two functions, you start to unlock some serious financial insights and make your operations a whole lot smoother.

- Smarter Capital Spending: When you know the exact condition and location of every piece of gear, you stop buying redundant equipment. No more "just in case" purchases that drain the budget. A practical example: a construction company realizes it doesn't need to rent an expensive generator because tracking data shows one is sitting idle at another job site just five miles away.

- Lower Carrying Costs: You can finally dial in your stock of spare parts and supplies. This prevents overstocking, which is just cash sitting on a shelf collecting dust. By setting automated low-stock alerts in a system like Resgrid, you can switch from bulk buying to a just-in-time model, dramatically reducing warehouse costs.

- Slash Downtime: By linking your maintenance schedules directly to your parts inventory, you ensure critical components are always on hand. This is huge for preventing costly delays when a vehicle or piece of equipment goes down. For a delivery fleet, this means avoiding a $500/day loss per vehicle by having the right tires in stock before a scheduled replacement.

The industry is already moving this way, and fast. The inventory management software market hit $3.9 billion in 2024 and is climbing, while the bigger asset management market is on track to blow past $27 billion by 2025. It's clear that getting a handle on your stuff is big business.

A Practical, Money-Saving Example

Here’s an actionable insight you can put to work right now: take a hard look at your preventive maintenance schedule and compare it directly with your spare parts inventory.

Let's say your records show three of your main vehicles are due for major service in the next 90 days. A quick check in a unified system like Resgrid might reveal you only have enough specialized filters and oil for one of them. By ordering the necessary parts now with standard shipping, you save hundreds on rush delivery fees. More importantly, you prevent vehicle downtime that could cost thousands in lost operational time.

This simple cross-reference is a perfect example of how assets inventory management turns data into real, tangible cost savings.

But tracking your gear is only part of the story. A truly comprehensive plan includes knowing what to do at the end of an asset's life. Properly disposing of outdated or broken equipment—especially electronics—is vital for data security and environmental compliance. Taking the time to understand What is IT Asset Disposition (ITAD) is a crucial step in mastering the entire asset lifecycle, from purchase to retirement.

The Core Pillars of a Modern System

A solid asset inventory management system is a lot more than just one piece of software; it's a strategic framework built on four crucial pillars. Think of it like building a high-performance car. You need a powerful engine, a strong chassis, a skilled driver, and a great navigation system. If you skimp on any one of those, you're not getting very far. In the same way, a modern management system needs each pillar working together to drive efficiency and cut costs.

This component-based approach gives you a clear blueprint for success, whether you're building a system from the ground up or just giving your current one a much-needed audit. Let's break down each of these core pillars.

Asset Tracking Technology

The first pillar is the tech that tells you where your assets are and what shape they're in. This is the "eyes and ears" of your whole operation, swapping out manual guesswork for hard, reliable data. Different technologies solve different problems, but they all share the same goal: giving you real-time visibility.

- Barcodes and QR Codes: This is the easiest place to start. A quick scan with a smartphone can check an asset in or out, update its location, or pull up its entire maintenance history. It's a low-cost, high-impact way to ditch the tedious paperwork and cut down on human error.

- Radio-Frequency Identification (RFID): RFID tags take things a step further, letting you scan a bunch of items at once without needing a direct line of sight. Picture a hospital instantly accounting for every piece of portable medical gear in a room just by walking past with a scanner. That's the power of RFID.

- Global Positioning System (GPS): For assets that are always on the move over large areas—think vehicles or heavy machinery—GPS is a must-have. It gives you live location data, tracks routes, and monitors how and when the equipment is being used.

An actionable insight for saving money: a construction firm can use GPS on its excavators to better manage deployment across a dozen job sites. By analyzing route data, they can optimize travel paths and monitor engine idle times, cutting annual fuel consumption by up to 15% and saving thousands of dollars.

Centralized Software Platforms

The second pillar is the "brain" of the operation: a central software platform that pulls in, organizes, and displays all your data. This is where all the information from your tracking tech comes together to create a single, unified view of every single asset and inventory item you own. Without this hub, you're just collecting data points in separate silos, which is almost as useless as having no data at all.

A modern platform should give you an intuitive dashboard with instant insights. For a practical example, a hospital could use a unified dashboard to track both its high-value medical devices (assets) and its disposable surgical supplies (inventory). This ensures life-saving resources are always where they need to be and that procurement teams can restock supplies ahead of time, preventing critical shortages and expensive last-minute orders.

A truly effective platform doesn't just hold data; it makes that data actionable. It should connect asset maintenance schedules with inventory levels, automate alerts for low stock, and provide a clear audit trail for every item.

Standardized Operational Processes

Let's be clear: technology by itself is not a magic bullet. The third pillar is all about creating simple, standardized processes that everyone on your team can actually follow, day in and day out. This means defining the "rules of the road" for how assets are requested, used, returned, and maintained. Clear processes are what ensure the data going into your system is accurate and reliable in the first place.

Take a busy manufacturing plant, for instance. A simple, clear checkout/check-in procedure for shared tools is essential. If one employee forgets to scan a tool when they bring it back, the system will show it as still in use. This leads to wasted time as others search for it and, eventually, probably buying a duplicate you didn't need. An actionable money-saving insight is to implement a "no scan, no return" policy that links directly to project budgets, ensuring lost tool costs are properly allocated and incentivizing careful tracking.

Reporting and Analytics

The final pillar is where you turn all that raw data into strategic intelligence. This is where your system delivers its greatest value—by helping you make smarter, data-driven decisions that directly save you money. Good reporting and analytics tools can spot patterns, uncover hidden inefficiencies, and help you predict future needs.

Imagine a logistics company analyzing its maintenance reports to discover that one specific model of delivery truck is breaking down 30% more often than the others. That single insight allows them to completely adjust their purchasing strategy and roll out a predictive maintenance schedule for the unreliable models, preventing costly roadside failures before they happen. This is just one example of how a robust platform can help you manage your assets. To see a full list of capabilities, you can learn more about Resgrid’s comprehensive features.

Implementing Your Management Process Step-by-Step

Switching over to a modern assets inventory management system isn't like flipping a switch. It's more of a journey that fundamentally changes how you see and handle your resources. If you follow a clear roadmap, you can make sure the implementation goes smoothly and starts delivering real results from day one.

The process boils down to six key steps, with each one building on the last to create a solid, sustainable system.

Conduct a Comprehensive Physical Audit

Your journey has to start with a truth-seeking mission: a complete physical audit. Before you can manage anything, you need to know exactly what you have. This means physically finding, identifying, and cataloging every single asset and inventory item your organization owns.

This step can be a real eye-opener. You'll probably uncover "ghost assets"—equipment that's on your books but has been long gone—or find duplicate supplies you never knew you had. A practical example: one office building audit found three brand-new, boxed printers in a storage closet, preventing a $1,500 purchase order for new ones. The whole point is to create an accurate baseline that will become the single source of truth for your new system.

Define Clear Business Goals

Once you have an accurate count of your stuff, the next step is to define what success actually looks like. Vague goals like "improve efficiency" just don't cut it. You need specific, measurable objectives that tie directly to your bottom line.

A clear goal could be reducing equipment downtime by 20% within the first year or cutting spending on duplicate tool purchases by 30%. These targets give you a clear direction for your implementation and concrete metrics to measure your return on investment. This clarity is crucial for getting your team on board and justifying the project's value.

Select the Right Technology Stack

Now it's time to pick the tools that will power your system. This decision should be driven by your specific goals and what you need to get the job done, not just flashy features. The right tech stack usually involves a mix of hardware and software working together.

- Tracking Hardware: This could be as simple as QR code labels you can scan with a smartphone, or more advanced options like RFID tags for automated tracking.

- Centralized Software: This is the heart of your system. A platform like Resgrid gives you a central dashboard to manage everything from asset locations and maintenance schedules to inventory levels.

The key is to choose technology that fits your budget and is easy for your team to actually use. For many, the growing Warehouse Management System (WMS) market has some powerful solutions. This sector is expected to hit $10.5 billion by 2030, which shows just how much demand there is for tech that brings order to complex operations.

Develop and Document Standardized Procedures

Even the best technology is useless if there aren't clear, simple rules for how to use it. This step is all about creating and documenting standardized operating procedures (SOPs) for your team. These procedures should cover everyday tasks like checking assets in and out, reporting maintenance issues, and requesting new inventory.

A well-documented process is the bridge between your technology and your team. It ensures consistency, reduces human error, and makes training new employees significantly easier.

Keep the procedures straightforward and easy to find. The goal isn't to create some massive, complex manual but a simple guide that makes everyone's job easier and ensures the data going into your system is accurate and reliable. For complex setups or specific questions, having comprehensive guidance is key; you can always get help by exploring the Resgrid support resources.

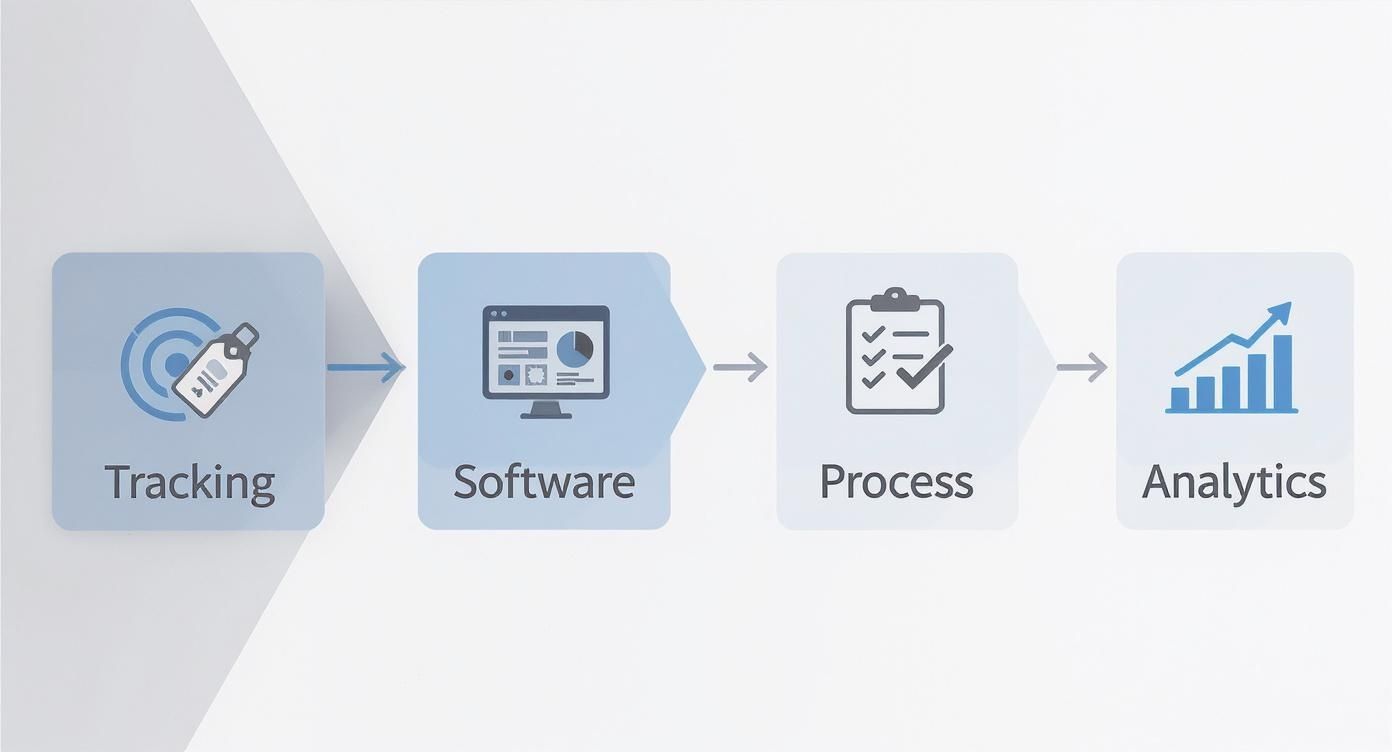

This infographic shows the core pillars that support a successful management process, from tracking technology to insightful analytics.

The flow highlights how each component—tracking, software, process, and analytics—interconnects to create a powerful, data-driven system.

Launch a Pilot Program

Instead of a big-bang, company-wide launch, start smaller with a pilot program. Pick a single department or a specific category of assets to test out your new system. This controlled rollout lets you train a small group of users, get valuable feedback, and iron out any issues before they affect your entire operation.

A practical example: a school district could pilot an asset management system with just the IT department's laptops and projectors. This allows them to perfect the check-out process and maintenance logging before expanding to include all school equipment, from science lab kits to sports gear. This low-risk approach ensures a smoother, more successful full implementation down the road.

Analyze Data and Continuously Improve

The last step isn't really an endpoint but a continuous cycle of improvement. Once your system is up and running, it will start spitting out a ton of data. Use this information to analyze performance, track your progress against the goals you set, and uncover new ways to save money and become more efficient.

For a practical, money-saving example, a manufacturing plant put a simple barcode system in place for its tools and spare parts. By looking at the checkout data, they realized that certain high-demand tools were constantly being searched for, wasting valuable technician time. They used this insight to create optimized tool kits for specific jobs, saving over $100,000 in the first year just from reduced search time and eliminating duplicate purchases. That's the real power of turning data into action.

Unlocking Tangible Cost Savings and Benefits

Putting a solid assets inventory management system in place isn’t just about getting organized—it’s a direct line to some serious financial and operational wins. Once you have a clear picture of every single asset and inventory item, you can start making smarter, data-backed decisions that put real money back into your budget. It’s all about shifting from reactive spending to proactive, strategic control over your resources.

This change creates a ripple effect of positive returns across the entire organization, from the folks on the front lines all the way to the finance department. The most immediate impact usually hits your capital spending. When you know exactly what equipment you have, where it is, and how it’s being used, you stop buying things you don't need and start getting the most out of what you already own.

Reducing Capital and Operational Spending

One of the biggest perks is the ability to slash unnecessary capital expenditures. A clear view of an asset's entire lifecycle—from the day you buy it to the day you retire it—prevents you from purchasing equipment that would just sit around gathering dust. This kind of visibility is a huge reason the global Asset Tracking and Inventory Management Solutions market is booming, projected to hit $5050.1 million by 2025. Organizations are waking up to the fact that real-time data is the key to smarter spending. If you're curious, you can discover more insights about asset tracking growth and see just how big this trend is.

Beyond the big-ticket purchases, a unified system chips away at day-to-day operational costs in a few critical ways:

- Eliminating Ghost Assets: These are the items that exist on your books but are nowhere to be found in the real world—they might be broken, lost, or simply vanished. An actionable insight is to perform a quick audit before renewing your insurance policy. Removing ghost assets from your register can lower your annual premiums by 5-10%.

- Minimizing Downtime: When you can link maintenance schedules directly to your spare parts inventory, you ensure critical components are always on hand. This proactive approach stops costly operational standstills before they can bring your production or services to a grinding halt.

- Optimizing Asset Utilization: Tracking data is fantastic at revealing which assets are being run into the ground and which are just sitting idle. Instead of buying new, you can reallocate that underused equipment, making sure you get maximum value from every dollar you've already spent.

A Practical Example of Immediate Savings

The financial impact becomes crystal clear when you look at a real-world scenario. Picture a large hospital network that's constantly losing track of its portable medical devices, like infusion pumps and vital signs monitors. Before they got a handle on it, departments would frequently report devices as "lost" and immediately request new ones just to keep things running.

After implementing an RFID tracking system, the network located hundreds of these "lost" devices. Turns out, they were just misplaced in other departments or tucked away in storage closets. This discovery allowed them to cut their annual budget for new portable medical devices by a staggering 20%, preventing countless unnecessary repurchases and saving hundreds of thousands of dollars in a single year.

Boosting Labor Efficiency and Compliance

The benefits don't stop with the equipment. An effective assets inventory management system automates a ton of the tedious, manual tasks that eat up your team's valuable time. Instead of spending hours hunting for tools, manually logging data, or doing physical counts, your staff can focus on what they were actually hired to do. A practical example: automating inventory counts can free up 40 hours of staff time per month, which can be reallocated to more productive, revenue-generating activities.

On top of that, rock-solid record-keeping is a lifesaver when it comes to regulatory compliance. For industries that need to maintain strict maintenance and inspection logs, a centralized system provides a verifiable audit trail that’s easy to access. This not only makes compliance reporting a breeze but also helps you dodge the hefty fines that come with messy or incomplete records. It turns a potential headache into a smooth, automated process.

Best Practices For Long-Term Success

Putting a new system in place is a great start, but getting real, long-term value out of it means committing to keeping it sharp. If you want your assets inventory management system to pay dividends for years to come, you need to build habits that keep it accurate, connected, and ready for what's next. These aren't just one-off tasks; they're strategies that turn a simple tracking tool into a strategic engine for your whole operation.

Ultimately, long-term success comes down to consistency and accountability. It’s all about creating workflows where collecting and analyzing data becomes second nature for your team, transforming raw numbers into smart, actionable decisions.

Establish a Regular Audit Cycle

An asset database is only as good as the information inside it. Over time, even the best systems can get out of sync with reality because of unrecorded moves, disposals, or just plain human error. Think of a regular audit cycle as your defense against this "data decay"—it's how you ensure your system stays the single source of truth you can count on.

A physical audit is pretty straightforward: you compare the gear you can physically touch to the records in your system. This process is fantastic for finding discrepancies, identifying "ghost assets" that are on the books but long gone, and checking the actual condition of your equipment.

- Quarterly Spot Checks: For your high-value or frequently moved assets, run quick spot checks every three months. It’s the best way to catch small issues before they become big problems.

- Annual Wall-to-Wall Audits: At least once a year, commit to a comprehensive, top-to-bottom physical inventory count. No stone left unturned.

An actionable insight for saving money: schedule your annual physical audit just before budget season. An accurate asset count allows you to make precise, data-driven purchasing requests, preventing over-budgeting and ensuring funds are allocated only where they are truly needed.

Integrate With Other Business Systems

Your assets inventory system shouldn't be an island. When you connect it with your other essential software, like accounting or an Enterprise Resource Planning (ERP) system, you get a complete, holistic view of your operations. This kind of integration streamlines workflows and uncovers much deeper financial insights.

A practical example: when a new asset is purchased, the data flows automatically from your accounting software right into the asset register. No manual entry needed. When that asset is retired, depreciation data syncs back for perfectly accurate financial statements. This eliminates double-work, cuts down on errors, and gives your finance team a real-time window into asset value. For any organization focused on data protection, it's vital to know how to maintain strong security protocols when linking multiple systems.

Leverage Mobile Technology For Field Updates

Work doesn't just happen at a desk anymore. Giving your field teams mobile access to the asset management system is a game-changer for maintaining real-time data accuracy. Mobile apps let technicians and operators update an asset's status, log maintenance, or check items in and out right from their phones or tablets, wherever they are.

For a practical example, a fire department can use a mobile app to log exactly which pieces of equipment were used at an incident scene. This instantly updates inventory levels for any consumables used and flags the primary asset for a post-incident inspection, making sure it’s ready for the next call.

This immediate data entry means there's no information lag. Every decision is based on the most current information possible, which directly saves money by cutting administrative overhead and preventing costly errors.

Create a Culture of Accountability

At the end of the day, technology is just a tool. It's the people using it who make it work. Building a culture of accountability around asset care and data accuracy is absolutely critical. This starts with clear training, standardized procedures, and making sure every single person on the team understands their role in keeping the system's data clean.

When employees view assets as shared resources that are vital to the mission, they’re far more likely to handle them with care and follow the tracking rules. For anyone serious about making their asset management a long-term win, it pays to implement proven strategies. You can explore some great ideas in these 10 IT Asset Management Best Practices for 2025 to help sharpen your approach. This sense of shared responsibility directly reduces asset damage, minimizes loss, and guarantees the data you're relying on is always trustworthy.

Common Questions About Assets Inventory Management

Even with the benefits laid out, I get it—jumping into a new system always brings up questions. It's only natural. Getting straight, practical answers is the best way to cut through the noise and feel confident about your next steps.

So, let's tackle some of the most common things people ask. These are designed to give you the clarity you need to make smart decisions, sidestep common headaches, and start seeing the payoff of a well-run system.

What Is the Real Difference Between Asset Tracking and Inventory Management?

People often use these terms interchangeably, but they're really two sides of the same coin. The easiest way to think about it is this: you track things you reuse, and you manage inventory you use up. One is about the life of an object, the other is about consumption.

Asset tracking is all about keeping tabs on your valuable, long-term equipment—the stuff you expect to last. Think vehicles, specialized tools, computers, or heavy machinery. The goal here is to know where these items are, what condition they're in, and when they need maintenance so you can squeeze every bit of value out of their service life.

Inventory management, on the other hand, deals with the consumable stuff. These are the items that get used and need to be restocked, like spare parts, office supplies, raw materials, or products you sell. The whole point is to keep just the right amount on hand—enough to do the job without tying up a bunch of cash in stuff that's just sitting on a shelf.

A truly effective system brings these two worlds together. It connects the maintenance schedule for a fire engine (an asset) directly to the real-time stock levels of its specific oil filters and brake pads (inventory). That way, the parts are always there when a mechanic needs them.

When you link them, two separate tasks suddenly become one seriously powerful operational tool.

How Can a Small Business Start Without a Huge Budget?

This is a big one. A lot of small businesses think you need a massive budget and fancy hardware to get started, but that's just not true. You can make huge improvements by starting small and being smart about it. The secret is to nail down your process first, then bring in the technology.

Your most powerful first step costs nothing: do a full physical audit with a simple spreadsheet. Just figure out exactly what you have and where it is. That gives you a baseline. From there, you can layer on some low-cost tech.

- Start with QR Codes: Forget expensive scanners. The smartphones your crew already has in their pockets are all you need. Simple QR code labels are dirt cheap and let your team check assets in or out, log a repair, or update a location with a quick scan.

- Embrace Cloud-Based Software: Modern platforms like Resgrid run on affordable monthly subscriptions. This gets rid of the big upfront software costs and the headache of maintaining your own servers. Plus, these systems are built to grow with you.

Here's an actionable insight for immediate savings: focus on your most critical or expensive assets first. The money you save by not losing or mismanaging just one of those key pieces of equipment can often pay for the system's subscription for an entire year. The return on investment can be almost immediate.

What Are the Biggest Mistakes to Avoid When Implementing a New System?

Rolling out a new system can be pretty smooth, but a few common missteps can completely derail the whole thing. If you know what they are ahead of time, you can steer right around them.

The three mistakes I see most often are ignoring your team, making things too complicated, and letting data entry get sloppy.

- Neglecting Team Training: You can have the best system in the world, but it's worthless if your staff doesn't get why it's important or how to use it. You have to invest time in training. Show them how it makes their job easier—like no more wasting 20 minutes hunting for a tool. If they don't buy in, they won't use it. Period.

- Choosing Overly Complex Software: It's tempting to get the software with all the bells and whistles. But the best tool is the one that solves your actual problems without getting in the way. A system that’s too complicated just means a brutal learning curve, people giving up on it, and you paying for features you'll never touch.

- Allowing Inconsistent Data Entry: The accuracy of your data is everything. If the data is garbage, the system is garbage. From day one, you have to set simple, strict rules for checking items in and out, logging maintenance, and updating locations. No exceptions. Inconsistent data makes the whole system unreliable and defeats the entire purpose.

Actively avoid these three traps, and you'll be setting yourself up for a successful launch that leads to real, lasting improvements.

Ready to gain complete control over your assets and inventory? With Resgrid, you get a powerful, scalable platform designed to unify your operations, reduce costs, and ensure your team always has the resources they need. See how our system can work for you at https://resgrid.com.