Fire Prevention Plan: Essential Guide to Protect People and Property

A fire prevention plan is so much more than a box-ticking exercise for compliance. Think of it as an active strategy—a living blueprint designed to protect your people, your assets, and the very future of your organization. It's the procedures you put in place before an incident happens, and the clear, actionable steps you take during one.

Why a Proactive Fire Strategy Isn't Optional

Simply put, your fire prevention plan is the first line of defense against a potential disaster. Waiting for an emergency to strike is a recipe for catastrophic loss, both in human and financial terms. Anyone who has seen the aftermath of a blaze understands that the process of commercial fire damage recovery is extensive, disruptive, and incredibly costly.

A proactive strategy shifts your entire organization from a reactive stance to one of genuine preparedness. And let's be clear, this isn't just about safety—it's smart business.

The financial upside of a robust, well-maintained plan goes far beyond just staying out of trouble.

- Lower Insurance Premiums: Insurance companies reward proactive risk management. When you can show them a well-documented plan, complete with regular training and equipment maintenance logs, they see you as a lower risk. For example, a documented quarterly sprinkler inspection and annual fire drill could lead to a 5-10% reduction in your premium, saving thousands per year.

- Keeps the Doors Open: A serious fire can shut down your operations for weeks, if not months. A solid prevention plan minimizes this risk, helping you avoid devastating downtime, lost revenue, and the very real possibility of losing your customers to competitors.

- Avoids Hefty Fines: Fire safety regulations aren't suggestions. Failing to comply can lead to significant financial penalties. A thorough plan ensures you're meeting all your legal obligations.

The Threat is Real and It's Growing

If you think this is an abstract problem, recent data tells a different story. Fire incidents are on a disturbing upward trend, making prevention more critical than ever.

In England, for example, fire and rescue services attended 620,758 incidents in the year ending September 2022. That's a 16% increase from the prior year. Even more concerning, the total number of actual fires recorded shot up by a staggering 28%. It's not just a UK problem, either. The U.S. saw its death rate from reported home fires climb by 16% in 2023. These numbers don't lie; our prevention plans have to keep pace with this escalating risk. If you want a broader view, you can dig into reports on the global fire protection market to see the growing demand for better systems.

A fire prevention plan isn't about predicting the future; it's about preparing for possibilities. The most effective plans are living documents, continuously updated as your organization evolves and new risks emerge.

This is the mindset that transforms your plan from a static document gathering dust on a shelf into a dynamic operational tool. It weaves together risk assessment, prevention controls, and emergency procedures into a cohesive system. Modern platforms can take this a step further, connecting your prevention efforts with real-time response capabilities, making sure every single person knows their role when seconds are the only thing that matters. That integration is what truly mitigates disasters.

Conducting a Practical Fire Risk Assessment

Every solid fire prevention plan starts not with buying new gear, but with taking a thorough, honest look at your own environment. A practical fire risk assessment is your roadmap, guiding every decision from here on out. It’s about getting past generic checklists and zeroing in on the real-world hazards unique to your operation.

Honestly, this is where you start saving money right away. When you pinpoint genuine threats, you can put your budget toward high-impact solutions instead of blowing it on upgrades that don't actually fix your vulnerabilities. For example, an assessment might reveal that the real risk isn't a lack of sprinklers, but the accumulation of cardboard in a specific corridor, a problem solved for free with a new housekeeping rule.

The goal is to answer three simple but critical questions:

- What could actually start a fire here?

- Who would be in danger if one did?

- What are we already doing, and is it really enough?

Thinking through this simple framework helps you methodically peel back the layers of your organization's day-to-day reality.

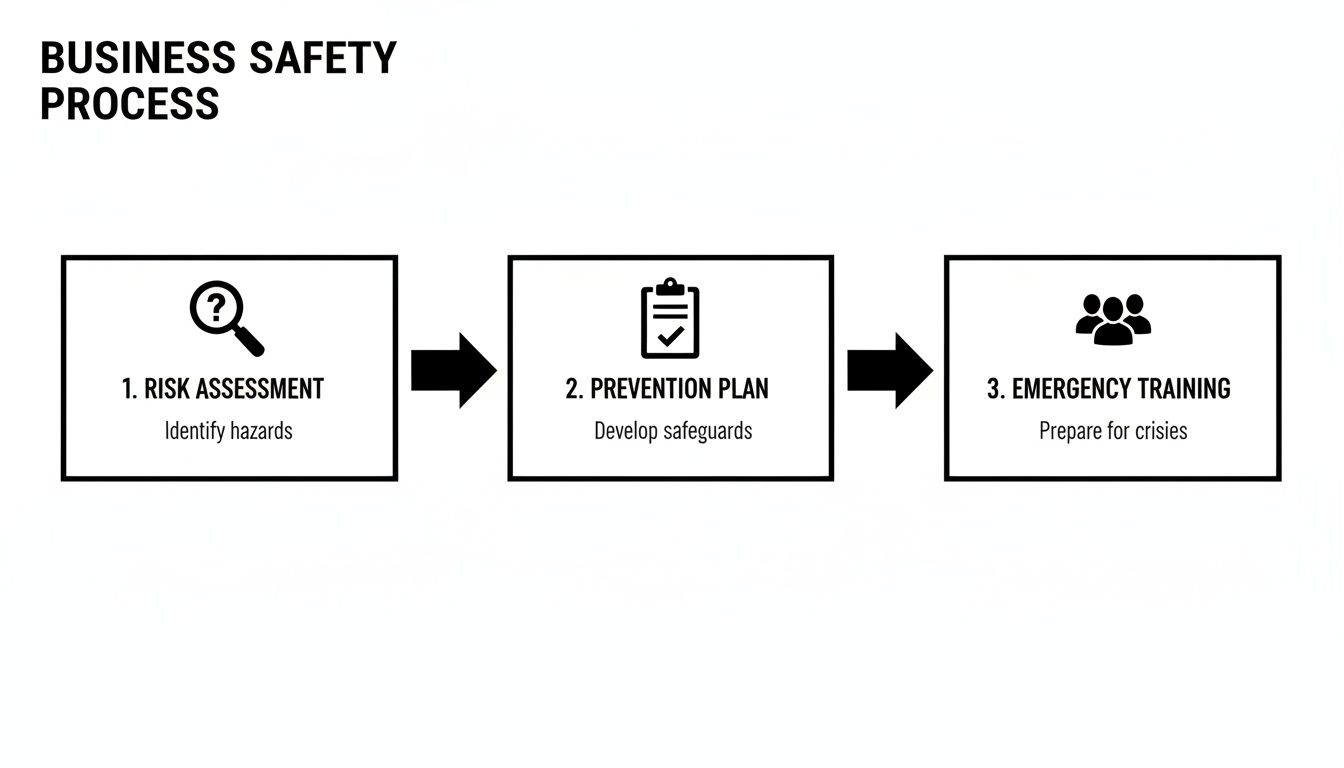

The whole process flows from this initial assessment to a state of ongoing readiness.

As you can see, a structured risk assessment logically leads to building a prevention plan, which is then reinforced through hands-on emergency training. It all starts with that first step.

Identifying Fire Hazards in Your Workplace

Start by walking through your entire facility with a critical eye, looking for potential ignition sources and fuel. This isn't a quick five-minute glance; it requires careful, deliberate observation. Think about things that change throughout the day, or even seasonally. For instance, it's a known fact that house fires increase during winter, and similar risks from heating systems can apply to commercial spaces, too.

Keep an eye out for these common—and often overlooked—risks:

- Electrical Equipment: Are computers and servers crammed into a closet with no ventilation? Check for those daisy-chained power strips tucked behind desks—they're a classic source of overloaded circuits. In a workshop, inspect cords on power tools for fraying or damage.

- Flammable Materials: Where do you keep cleaning supplies, chemicals, or paints? A workshop storing oily rags in an open bin is a textbook fire hazard just waiting for a spark. They need to be in designated, sealed metal containers.

- Heat Sources: This includes the obvious stuff like kitchen equipment in a breakroom, but also less obvious sources like HVAC units or heavy machinery that can overheat without proper maintenance.

- Human Error: Are designated smoking areas located a safe distance from buildings and anything combustible? Do employees understand the danger of blocking fire exits with inventory, even "just for a minute"?

A great risk assessment isn't just a list of problems. It’s a detailed story of how your business operates, complete with potential plot twists you need to prepare for. Documenting these findings with photos and specific locations is crucial.

Evaluating Who Is at Risk

Once you've identified the hazards, the next step is to think about the people who could be harmed. Your responsibility goes way beyond your full-time employees. You have to account for every single person who might set foot in your space.

Think about these different groups and their unique vulnerabilities:

- Employees: Consider those working directly with hazardous materials or high-heat equipment. Do they have the right training and personal protective equipment (PPE)?

- Lone Workers: What about an overnight security guard or a maintenance worker on a quiet weekend shift? Their situation is completely different, and their ability to get help or evacuate might be seriously delayed.

- Visitors and Customers: The public has no idea about your layout or emergency procedures. Crystal-clear exit signage is non-negotiable, especially in retail or any public-facing environment.

- People with Disabilities: Are your evacuation routes truly accessible? Do you have procedures in place, like designated assistants, to help those with mobility challenges get out safely?

A detailed assessment of these groups will directly shape your emergency procedures and training modules. This foresight ensures your fire plan is inclusive and protects everyone—not just the majority. By clearly documenting these specific risks and vulnerable populations, you build a powerful case for targeted, cost-effective safety investments that will actually make a difference.

Implementing Cost-Effective Fire Prevention Controls

Once you’ve nailed down the hazards in your risk assessment, it's time to put practical controls in place. This isn't about breaking the bank; it’s about making smart, targeted investments that neutralize threats before they ever have a chance to grow. A solid fire prevention plan layers different types of controls on top of each other, creating a really robust safety net.

These proactive measures are where you see a clear and immediate return. Think about it: effective controls directly slash the odds of a fire starting in the first place. That translates into real financial benefits—lower insurance premiums, avoiding hefty regulatory fines, and preventing the kind of costly downtime that can cripple an operation.

Engineering Controls: Your First Line of Defense

Engineering controls are the physical systems you build right into your facility. They work automatically to detect, suppress, or contain a fire, making them your most reliable and passive forms of protection. They're on the job 24/7, no human intervention required.

I like to think of them as silent guardians:

- Automatic Sprinkler Systems: These are the gold standard for a reason. They activate directly over a heat source, often knocking down a fire before it can spread. In a warehouse, that's the difference between losing a single pallet and losing an entire section of inventory.

- Fire and Smoke Alarms: Modern systems are so much more than just noise makers. They can automatically notify the fire department and tie into other building systems, like shutting down the HVAC to stop smoke from circulating.

- Fire Doors and Barriers: These are specially built barriers designed to compartmentalize a building. They contain a fire to one specific area for a set amount of time, buying you invaluable minutes for evacuation and for first responders to arrive.

A perfect example of a crucial engineering control in an office or data center is electrical load management. By using smart power distribution units (PDUs) and ensuring server racks have proper ventilation, you prevent the kind of overheating that leads to electrical fires—a common and incredibly destructive hazard.

Administrative Controls: Guiding Human Behavior

While engineering controls manage the physical space, administrative controls are all about managing people. These are the policies, procedures, and rules you put in place to encourage safe behavior and cut down on human error—a factor in nearly nine out of ten wildfires.

These controls are often low-cost but have a massive impact:

- Clear 'No Smoking' Policies: It sounds simple, but establishing and strictly enforcing designated smoking areas far away from building entrances and flammable materials is a game-changer.

- Hot Work Permit System: For jobs like welding or grinding that create sparks, a formal permit system is a must. It ensures someone has checked the area for combustibles and made sure a fire extinguisher is ready to go before the work starts.

- Good Housekeeping Practices: This is all about routine. Having set procedures for disposing of oily rags, keeping hallways and exits clear of clutter, and properly storing chemicals makes a huge difference. A clean, organized workspace is an inherently safer workspace.

The most powerful administrative controls are the ones woven directly into your company culture. When safety becomes everyone's responsibility, your fire prevention plan stops being a document on a shelf and becomes a daily practice. That’s how you drastically reduce risk without a huge capital expense.

To give you a sense of where things are heading, the global fire protection system market was valued at USD 88.945 billion in 2024 and is projected to climb to USD 130.369 billion by 2030. That growth is being fueled by stricter regulations and a much bigger organizational focus on safety. We're seeing a major shift toward smart, connected systems that help teams get ahead of problems.

The final piece of the puzzle is tying all these controls together. Exploring the features of a dispatch and management system like ours can show you how to connect your prevention protocols with real-time communication and response coordination. It ensures your plan actually works flawlessly when it matters most.

Defining Clear Emergency Roles and Procedures

When an alarm blares, panic is the real enemy. It's the confusion that can be just as dangerous as the fire itself. A well-thought-out fire prevention plan is your antidote to chaos, shifting your team from panic to purpose by defining exactly what to do and who does it. This clarity doesn't just save lives; it minimizes property damage and drastically cuts down on recovery time.

The core principle here is simplicity. Your emergency procedures have to be so straightforward that people can follow them under extreme stress. Forget the thick binder of rules nobody reads. Think clear, visual, and instinctual actions.

Mapping Effective Evacuation Routes

The foundation of any emergency procedure is a clear path to safety. Everyone—from a new hire on their first day to a one-time visitor—must be able to find their way out quickly, without a second thought.

You'll want to start by creating simple, color-coded floor plans. These aren't architectural blueprints. They are simple diagrams posted in high-traffic spots like break rooms, hallways, and near elevators.

Here’s what every good evacuation map needs:

- Primary and Secondary Exits: Always assume the most obvious path might be blocked. You need to clearly mark at least two escape routes from every major area.

- "You Are Here" Markers: This sounds obvious, but it’s surprisingly easy to forget. It’s absolutely crucial for orienting someone who is panicking or just doesn't know the layout.

- Location of Fire Safety Equipment: Show people where to find fire extinguishers, pull alarms, and first-aid kits. This empowers anyone to take immediate action if they can.

- Designated Assembly Points: The evacuation isn't over until everyone is accounted for. Designate a specific, safe location—or even two—away from the building where everyone must gather. A parking lot across the street or a nearby park are common choices.

A classic mistake I see is choosing an assembly point right next to the building. That can interfere with emergency responders and put your people in the path of smoke or debris. Pick a spot far enough away to be safe, but close enough to be reached easily.

Establishing Mission-Critical Roles

Without assigned roles, you get the bystander effect—everyone just assumes someone else is taking charge. Your fire prevention plan has to break that cycle by assigning specific responsibilities so that key actions happen automatically.

Let's walk through a scenario: A busy retail store.

Imagine a fire alarm shrieks during a peak Saturday afternoon. Without defined roles, you get pure chaos. Customers might ignore it, and employees will just look at each other for direction, wasting precious seconds.

Now, let's replay that with clear roles assigned:

- Fire Warden (e.g., Department Supervisors): Their first job is to sweep their zone, directing customers toward exits and quickly checking restrooms or stockrooms. They should wear a high-visibility vest to be easily identified.

- Floor Manager: This person’s sole focus is to confirm 911 has been called and to meet first responders at the entrance with building keys and critical information. They are the single point of contact.

- Cashiers/Front-End Staff: Their procedure is simple: calmly guide customers in their immediate area toward the nearest exit and then head to the assembly point themselves.

This division of labor ensures everything—evacuation, communication, and liaising with emergency services—happens in parallel. It transforms a mad scramble into a coordinated response.

Streamlining Emergency Communication

How you communicate during a fire is just as important as your evacuation routes. A modern plan should integrate technology to make sure information flows instantly to the right people.

Using a dispatch and management platform like Resgrid allows for immediate, targeted communication. The moment an alarm is triggered, an automated alert can hit the mobile devices of all your fire wardens and managers.

This isn't just about speed; it's about control. A manager can use the platform to:

- Conduct a Digital Roll Call: At the assembly point, fire wardens can use their phones to quickly check off employees as "safe," instantly identifying who might be missing. That information gets relayed to first responders in real-time, focusing their search efforts where they're needed most. This single feature can save tens of thousands in operational downtime by providing a clear "all clear" to emergency services faster.

- Share Critical Updates: If an exit is blocked by smoke, a manager can send a broadcast message to all staff phones: "DO NOT USE WEST EXIT. Evacuate via main entrance only." This simple action prevents people from running straight into danger.

This level of instant coordination is impossible with old-school methods like shouting or word-of-mouth. It saves critical seconds, reduces the overall impact of the incident, and gives you a clear record of the actions taken—which is invaluable for post-incident analysis and insurance claims.

Setting Up Your Training and Maintenance Schedule

Let's be blunt: a fire prevention plan gathering dust in a binder is completely useless. It’s only as good as the people who know how to execute it and the equipment they have to rely on. If your team doesn't know their roles or a critical fire extinguisher is dead, that plan means nothing.

This is why a consistent, documented schedule for both training and maintenance isn't just "best practice"—it's the absolute backbone of your entire safety strategy.

Holding one annual meeting and calling it "training" just doesn't cut it. Real, effective training builds muscle memory, which is what allows your team to act decisively and correctly when the pressure is on. In the same way, routine maintenance catches the small issues—a loose connection, a low battery—before they turn into catastrophic failures during a real emergency. This isn't just about safety; it's smart business. Being proactive saves a ton of money by preventing equipment failures and helping your staff minimize damage.

Designing a Training Program That Actually Works

The goal here is to get people out from behind a desk and into hands-on, practical application. Your team needs to feel the weight of a fire extinguisher, they need to physically walk the evacuation routes. I've found that a blended approach, mixing a few different methods, is the best way to keep everyone engaged and truly prepared.

Try to incorporate a mix of these training styles:

- Hands-On Fire Extinguisher Practice: This is a game-changer. Partner up with a local safety vendor to run a live fire training session. Letting employees use a real extinguisher on a small, controlled fire is an experience a video or PowerPoint can never, ever replicate.

- Simulated Evacuation Drills: Run these at least twice a year, and try to mix up the timing. A drill during a shift change or over a lunch break can expose some surprising bottlenecks and communication breakdowns that a perfectly planned, orderly drill would miss entirely.

- Tabletop Exercises for Managers: Get your leadership team in a room and talk through a fire scenario. Start asking the "what if" questions. What if the primary exit is blocked? What if the fire warden for the second floor is on vacation? This is how you build critical thinking skills for your key responders.

The real value of a drill isn't in a perfect execution—it's in what goes wrong. Every mistake made during a practice run is a potential disaster averted in a real emergency. Document these findings and use them to refine your plan.

Establishing an Ironclad Maintenance Schedule

Your fire protection equipment is your silent guardian, always on watch. It demands consistent attention. A single missed inspection on a sprinkler system or a dead battery in an emergency light can have devastating consequences. A detailed, recurring maintenance schedule is simply non-negotiable.

This is one area where automation can be a huge help and a major cost-saver. Manually tracking dozens, or even hundreds, of assets is an administrative nightmare just waiting for human error. Using a platform that offers powerful dispatch and management applications lets you put these schedules on autopilot. You can set up recurring inspection tasks for specific gear, assign them to the right people, and get automatic alerts when something is overdue.

What you get is a verifiable digital audit trail. This proves your due diligence, which can even help lower your insurance premiums. More importantly, it saves hundreds of administrative hours and gives you peace of mind that nothing is falling through the cracks. Imagine replacing a paper-based system that takes a manager 10 hours a month with an automated one that takes one hour. That's a direct payroll saving of over 100 hours a year.

Here’s a sample checklist you can adapt for your own facility.

| Equipment | Frequency | Key Checks |

|---|---|---|

| Fire Extinguishers | Monthly (Visual) | Ensure the extinguisher is visible, unobstructed, and the pressure gauge is in the green. |

| Smoke & CO Alarms | Monthly (Test) | Press the test button to ensure the alarm sounds. Replace batteries annually. |

| Emergency Lighting | Monthly (Test) | Activate the lights for at least 30 seconds to ensure they illuminate. |

| Sprinkler Systems | Quarterly (Visual) | Check that sprinkler heads are not painted over, damaged, or obstructed by storage. |

By committing to a regular rhythm of both training and maintenance, you transform your fire prevention plan from a static document into a dynamic, living system. It's this ongoing effort that builds true resilience and protects your people and property when it counts.

Got Questions About Your Fire Plan? We've Got Answers.

Even with the best guide, putting together a fire prevention plan always sparks a few questions. That’s perfectly normal. Every building is different, every team has its own quirks, and regulations can feel like a moving target. Getting these common questions answered upfront can be the difference between a plan that just checks a box and one that actually works when it matters.

Let's dig into some of the most frequent questions we hear. My goal is to give you clear, practical answers that get you unstuck and confident in the safety strategy you're building.

How Often Should We Update Our Plan?

Think of your fire prevention plan as a living document, not a "set it and forget it" task. At the absolute minimum, you need to pull it out for a full review annually. This keeps it in sync with any changes to your space, your people, or local fire codes.

But some things just can't wait for the annual review. You need to update your plan immediately if any of these happen:

- You Change Your Layout: Renovating the building, putting up new walls, or even just reconfiguring a big open-plan office means your evacuation maps are now wrong. Risks have shifted, and your plan needs to reflect that.

- You Bring in New Hazardous Materials: The minute a new chemical or process comes on-site, you’ve got to do a risk assessment. Your plan needs to spell out exactly how to store and handle it safely.

- Key People Change Roles: If your designated fire warden or emergency coordinator leaves, you can't leave that role vacant. Reassign it and update the plan right away so everyone knows who’s in charge.

One of the most common—and dangerous—mistakes is letting a fire plan gather dust on a shelf. An annual review is your baseline, but treating it like a dynamic tool that evolves with your organization is how you stay genuinely prepared.

What's the Single Biggest Mistake Companies Make?

Hands down, the biggest failure we see is a lack of effective training. It's a classic scenario: a company spends a ton of time writing a beautiful, detailed plan and installs the best equipment, but then completely drops the ball on teaching their team what to do.

A plan that only exists on paper is useless in a real fire. When alarms go off, people don't rise to the occasion; they fall back on their training. If there's no training, they fall back on panic, and that's where even the best-laid plans crumble.

I once saw a manufacturing plant with a perfect evacuation map. On paper, it was flawless. But they never ran a drill. If they had, they would have discovered that the main emergency exit on the west side of the building was consistently blocked by pallets every single afternoon during the shift change. A live drill would have exposed that simple, deadly problem in five minutes. That’s why training turns your plan from theory into instinct.

How Can We Make Our Fire Drills More Effective?

If you want to get real value from your drills, you have to throw a few curveballs. A drill announced a week in advance where everyone calmly walks to the assembly point doesn't test anything. It just proves people can follow simple directions when there's no pressure.

Try these tactics to make your next drill count:

- Block an Exit. Before the drill, tape a sign on a primary exit door that reads, "EXIT BLOCKED BY FIRE. USE ALTERNATE ROUTE." This forces people to stop, think, and actually use the secondary escape path they're supposed to know.

- Vary the Time. Stop running drills at 10 a.m. on a Tuesday. Kick one off during lunch when half the team is out, or 15 minutes before closing time. You'll quickly see how your response changes with a skeleton crew or during a chaotic shift change.

- Use Observers. Designate a couple of managers or safety leads to sit out the drill. Their job is to watch and take notes. Where did people get confused? Where did bottlenecks form? Did the fire wardens actually take charge?

The feedback you get from drills like these is gold. It shows you exactly where the weak spots are in your plan. For more complex scenarios and guidance, you can always find great resources in the Resgrid support documentation.

Do We Really Need a Plan for Our Small Office?

Yes. 100% yes. Your responsibility for keeping people safe doesn't disappear just because you have a small team. A five-person office obviously doesn't need the same beast of a plan as a 500-person factory, but the core principles are exactly the same.

Even the simplest small office plan needs to cover the basics:

- Clear escape routes and a designated meeting spot outside.

- The locations of every fire extinguisher and smoke alarm.

- A clear policy on who is responsible for calling 911.

- A plan for getting any visitors or clients out safely.

The scale is smaller, but the need for clarity in a crisis is universal. A simple, well-communicated plan is infinitely better than no plan at all. It's a fundamental part of your duty of care.

A solid fire prevention plan is a cornerstone of a resilient and safe workplace. When you pair those practices with a modern communication system, you ensure your team is always connected and ready to act. Resgrid gives you the tools to coordinate your response, account for your people, and manage incidents in real-time, turning that document on the shelf into a life-saving strategy. Learn more at https://resgrid.com.